Whale Tail vs Cam Lock: Truck Tool Box Lock Comparison 2026

Table of Contents

- Defining the Lock Types: Whale Tail vs. Cam Lock Fundamentals

- Structural and Mechanical Differences in Operation

- Comparative Security, Anti-Theft, and Tamper Resistance

- Durability and Environmental Resistance in Heavy-Duty Use

- Installation Requirements and Compatibility with Toolbox Designs

- Ergonomics, User Interface, and Operational Convenience

- Cost Analysis and Long-Term Return on Investment (ROI)

- Selecting the Right Mechanism: Application-Specific Criteria

Defining the Lock Types: Whale Tail vs. Cam Lock Fundamentals

Selecting the appropriate locking mechanism is critical for the security, usability, and longevity of commercial vehicle tool boxes, industrial enclosures, and specialized equipment compartments. The choice often narrows down to two dominant categories in the heavy-duty sector: the Whale Tail compression latch and the simple Cam Lock.

Understanding the fundamental design and function of each is the first step toward an informed procurement decision.

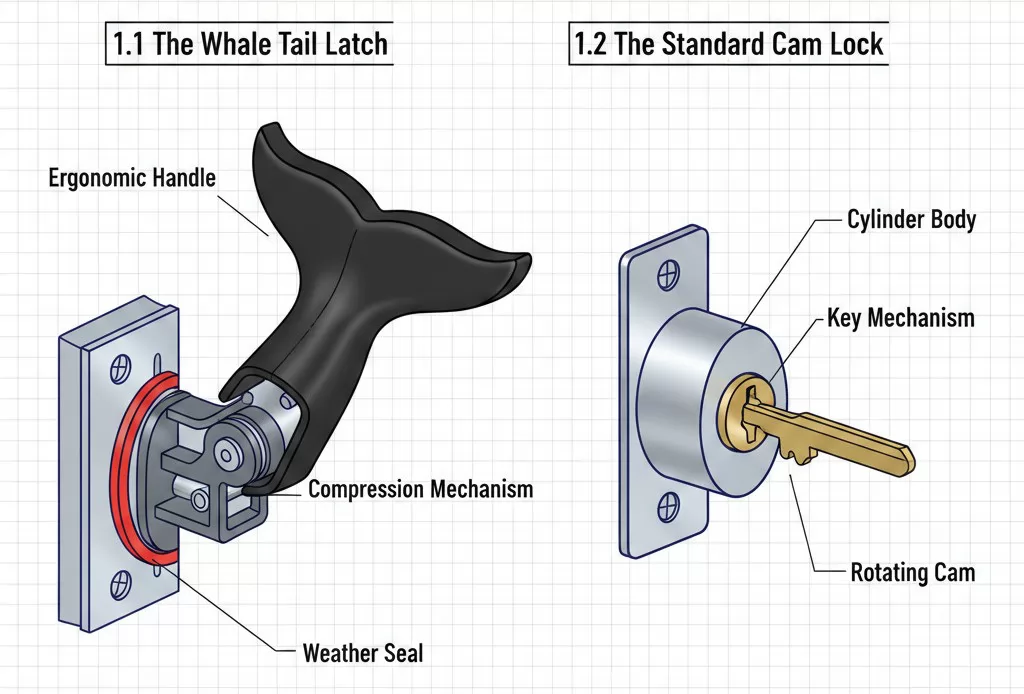

1.1 The Whale Tail Latch: Compression and Ergonomics

The Whale Tail latch, often referred to as a Whale Tail handle or compression latch, is a three-dimensional assembly characterized by its distinct, ergonomic handle shape—resembling the fluke of a whale. It is a robust mechanism designed for applications requiring high sealing force and resistance to vibration.

- Core Function: It serves not only as a latch to hold the door or lid closed but also as a handle for manual operation.

- Key Mechanism: When operated, the handle turns a cam or roller that engages with a strike. More importantly, it often incorporates a compression feature. As the handle reaches its fully closed position, it pulls the door tightly into the frame, compressing the seal gasket.

- Primary Benefits: Superior sealing against dust and water (IP ratings), and anti-vibration performance, making it ideal for rough-road commercial transport and external environments.

1.2 The Standard Cam Lock: Simplicity and Versatility

The Cam Lock, or cylinder lock, is one of the most widely used and simplest locking devices. It consists of a barrel (cylinder) housing the key mechanism, to which a straight or offset flat metal piece—the cam—is attached.

- Core Function: It is purely a locking mechanism that restricts the rotation of the cam until the correct key is inserted and turned.

- Key Mechanism: When the key is turned, the attached cam rotates 90 or 180 degrees, moving from a vertical (locked) position to a horizontal (unlocked) position, or vice versa, either engaging or disengaging a strike plate on the frame.

- Primary Benefits: High cost-effectiveness, compact size, and wide adaptability. They are simple to install and come in a vast range of cylinder lengths and cam styles.

The fundamental distinction lies in their operation: the Whale Tail integrates the latch, handle, and often a compression seal; the Cam Lock is a discrete, key-operated security device requiring a separate handle or pull mechanism.

Structural and Mechanical Differences in Operation

The operational mechanism dictates the overall performance characteristics—security, vibration resistance, and sealing—of a lock in industrial environments. Comparing the internal workings of the Whale Tail latch and the Cam Lock reveals why each is suited for specific applications.

2.1 Mechanical Engagement and Sealing Force

The most significant mechanical difference is the method of engagement and the resulting force applied to the door and frame.

- Whale Tail Latch: This mechanism typically uses a multi-point engagement system. The handle rotates an internal rod that drives one or more locking points (either cams or fixed bolts) simultaneously. Crucially, the compression feature creates a powerful seal. This action counters the warping or misalignment often seen in large truck boxes and ensures a weather-tight closure. The complexity allows for higher resistance to prying.

- Cam Lock: The Cam Lock utilizes a single-point engagement (the cam itself). It does not inherently generate compression force; it only stops the door from opening. The seal quality is entirely dependent on the quality of the surrounding gasket and the force applied by the operator when closing the door, not the locking mechanism itself.

2.2 Internal Components and Construction

The internal componentry reflects the intended use and robustness of the assembly. For heavy-duty applications, material and construction quality are paramount.

| Component Aspect | Whale Tail Latch | Standard Cam Lock |

|---|---|---|

| Material Complexity | Often zinc alloy or stainless steel with internal rods, multiple cams, and a complex gear or rotary mechanism. High component count. | Typically simple brass or zinc cylinder housing with a steel or brass cam plate. Low component count. |

| Key Cylinder Integration | The key cylinder is integrated into the handle assembly, often protected by a dust/weather cap, and controls the locking of the handle itself. | The key cylinder is the lock. It controls the rotation of the cam directly. |

| Mechanical Travel | Significant mechanical travel (rotation of the handle) is required to achieve full engagement and compression. | Minimal mechanical travel (90° or 180° turn of the key) is required to shift the cam from locked to unlocked. |

2.3 Resistance to Dynamic Loads (Vibration)

Truck tool boxes are subject to continuous vibration and shock. The Whale Tail’s compression action eliminates clearance between the door and frame, significantly reducing rattling and component wear due to dynamic loads.

In contrast, a standard Cam Lock, relying solely on single-point engagement, is more susceptible to rattling under severe vibration if not paired with a highly effective door stop or buffer. Over time, constant movement can accelerate wear on the cam and strike plate.

Comparative Security, Anti-Theft, and Tamper Resistance

For high-value tools and sensitive equipment stored in truck boxes, security is often the paramount concern. The inherent design differences between the Whale Tail and the Cam Lock translate directly into varied levels of security and resistance to common intrusion techniques.

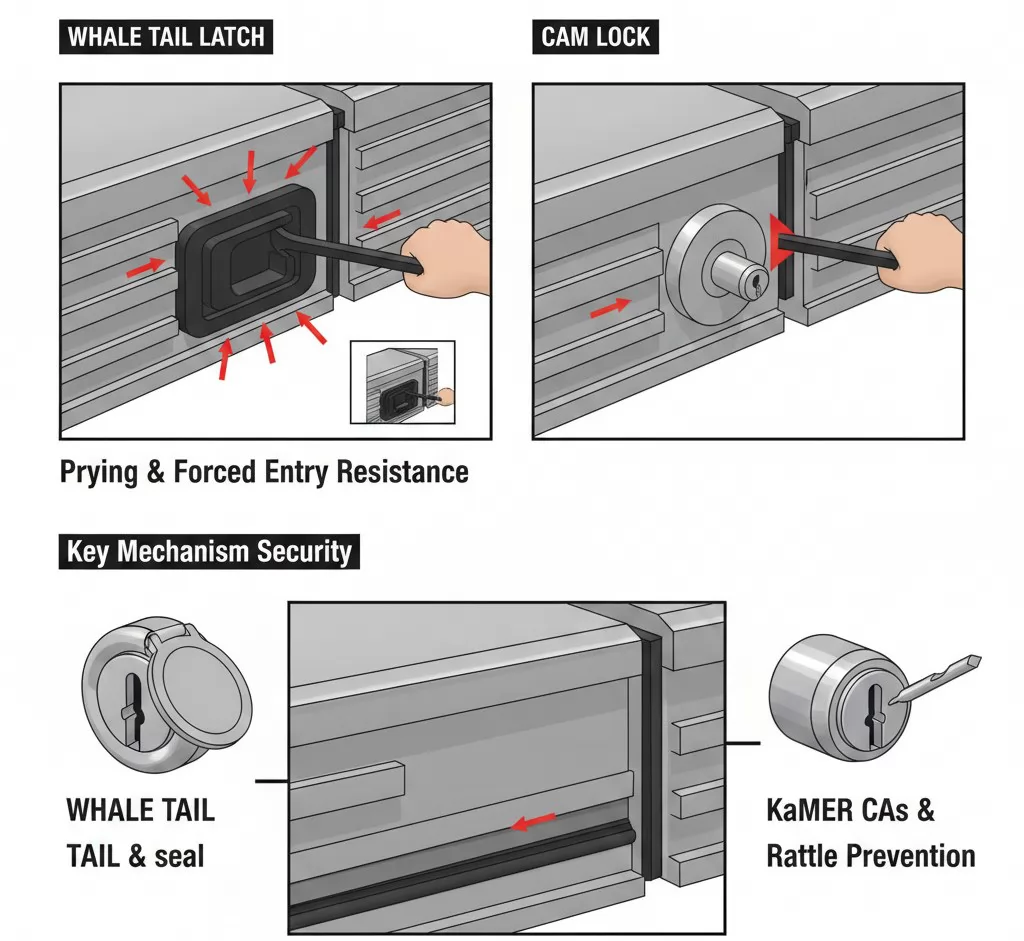

3.1 Prying and Forced Entry Resistance

Prying is the most common method of forced entry on truck boxes. The lock's ability to resist leverage is key to its security rating.

- Whale Tail Latch: Due to its large footprint and integration into the door panel, the Whale Tail distributes force across a wider area. If it is a multi-point locking system, the prying force applied at the handle must overcome engagement at two or three separate points, making brute-force entry significantly more difficult. The recessed nature of most Whale Tail handles also limits the surface area available for tools.

- Cam Lock: Standard Cam Locks are inherently vulnerable to prying because they engage at only one point. A determined intruder can often use a leverage tool to bend the door or the frame near the cam, forcing the cam past the strike plate. The security is highly dependent on the thickness and stiffness of the door panel material surrounding the lock.

3.2 Key Mechanism Security (Lock Picking)

Both systems rely on cylinder locks, which can be specified with varying degrees of complexity.

- Cylinder Quality: Both the Whale Tail assembly and the Cam Lock can be fitted with standard wafer tumblers, pin tumblers, or high-security disc detainer cylinders. However, due to its price point, the standard Cam Lock is often supplied with lower-security wafer locks, which are easier to pick or bypass. Procurement specifications should always stipulate the required cylinder type (e.g., restricted keyway, hardened steel pins).

- External Exposure: The Cam Lock cylinder is typically exposed directly on the surface, making it susceptible to drilling or destructive attacks. Many Whale Tail designs incorporate a protective housing or a rotating dust cover that shields the keyway, offering a minor deterrent against initial destructive attempts.

3.3 Tamper and Rattle Prevention

The compression feature of the Whale Tail offers a clear advantage in preventing tampering related to movement.

By pulling the door tightly against the seal, the Whale Tail ensures zero slack in the door-to-frame connection. This eliminates the rattling that could signal to an observer that the door seal is compromised or that the latch is nearing failure, and prevents opportunistic 'shimming' by eliminating the gap entirely.

Conversely, a loose-fitting Cam Lock system can be exploited via shimming or manipulation if excessive door gap is present.

Durability and Environmental Resistance in Heavy-Duty Use

For external, heavy-duty applications like truck tool boxes, durability is measured by a lock's ability to resist environmental degradation and continuous mechanical cycles. The material selection, finishing process, and inherent design structure of each lock type determine its long-term reliability.

4.1 Water and Dust Ingress Protection (IP Rating)

Protection against elements is often the primary reason procurement specifies a higher-end latch.

- Whale Tail Latch: This design is fundamentally better suited for achieving high Ingress Protection (IP) ratings (e.g., IP65, IP66). The compression action forces the door against a high-quality perimeter gasket, physically sealing the enclosure. Furthermore, the external mechanism is often designed with minimal gaps and sometimes features internal drip edges to divert water.

- Cam Lock: A standard Cam Lock requires the integration of a separate gasket and relies on the mounting position to prevent water ingress through the lock cylinder itself. While a good quality Cam Lock can achieve a satisfactory IP rating (often through integrated O-rings on the barrel), it does not contribute to the overall door seal like a compression latch does. They are generally less effective in maintaining a high-level seal under pressure or continuous washing.

4.2 Material Selection and Corrosion Resistance

The operational lifespan in environments exposed to road salts, harsh weather, and industrial chemicals necessitates robust materials.

- Standard Materials: Both Whale Tail latches and Cam Locks are commonly manufactured using materials such as zinc-plated steel, zinc alloy (die-cast), or stainless steel (304 or 316 grade). For demanding applications, stainless steel components are mandatory for superior resistance to rust and pitting, which is particularly relevant for the exterior handle of the Whale Tail.

- Finish Quality: Powder coating and high-grade chrome plating are essential for zinc parts to extend life. Buyers should specify the minimum salt spray resistance hours required (e.g., 500 hours or 1000 hours).

4.3 Resistance to Wear and Tear

Mechanical wear affects the reliability of the locking action over thousands of cycles.

The multi-component nature of the Whale Tail—involving pivots, cams, and rods—means that wear points are distributed. High-quality latches use robust internal components (e.g., stainless steel shafts) to minimize play. Conversely, a Cam Lock's wear is primarily concentrated on the small cam and the strike plate. Constant heavy use can cause the cam to deform or the lock to become loose, leading to unreliable locking engagement.

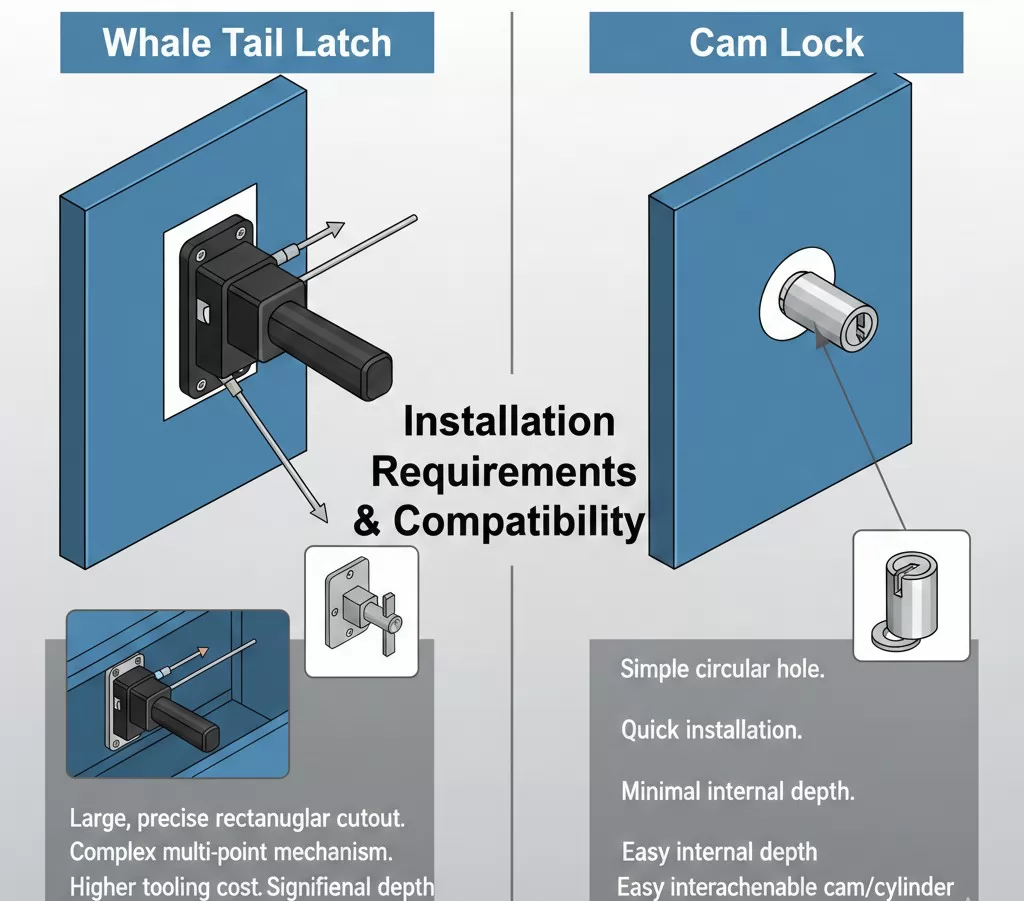

Installation Requirements and Compatibility with Toolbox Designs

From an OEM and manufacturing perspective, the ease of installation, panel cutout requirements, and overall compatibility with existing toolbox designs are crucial factors affecting production costs and scalability. Whale Tail latches and Cam Locks present significantly different integration challenges.

5.1 Panel Cutout and Mounting Complexity

The footprint and required panel preparation are starkly different for the two types of hardware.

- Whale Tail Latch: Requires a larger, often rectangular, and more precise cutout. Since the mechanism integrates the handle and internal locking components, the cutout must accommodate the entire body of the latch. If the latch uses internal rods for multi-point locking, additional holes or mounting points for rod guides and strikes are required on the door frame. This complexity means higher initial tooling costs for the panel.

- Cam Lock: Requires a simple, circular hole for the lock cylinder barrel, typically stabilized by a small keyway notch (or two flats). Installation is quick, usually involving only a securing nut or clip on the back of the panel. This minimal modification makes it highly versatile across various sheet metal and enclosure designs.

5.2 Depth and Space Considerations

The internal protrusion of the lock mechanism can impact the usable space within the tool box.

- Internal Rods and Linkages: High-security Whale Tail latches often require significant space behind the panel to accommodate the handle mechanism, rods, and rotating strikes. This must be factored into the internal dimensions of the box, especially for shallow compartments.

- Cam Lock Simplicity: The standard Cam Lock requires only minimal depth behind the panel, determined by the length of the cylinder and the sweep of the cam. This makes it ideal for tight spaces and thin-walled enclosures where internal clearance is limited.

5.3 Interchangeability and Customization

For fleet management and standardized production, the ability to easily swap components is a benefit.

Cam Locks offer superior interchangeability. Cylinders can often be swapped out quickly to rekey an entire fleet without replacing the entire housing. Furthermore, the cam itself can be easily replaced with different offsets and lengths to suit varying door/frame dimensions.

Whale Tail latches, being proprietary assemblies, offer less flexibility. While the internal key cylinder might be replaceable, the entire latch assembly is typically specific to the manufacturer and model, limiting easy cross-brand or cross-model substitution.

Ergonomics, User Interface, and Operational Convenience

While engineers prioritize security and durability, procurement managers and end-users value ease of use, especially in environments where operators wear gloves or frequently access the compartments. Ergonomics and operational convenience differ substantially between the two lock types.

6.1 Hand Engagement and Operation

The Whale Tail latch provides a superior user interface for large, heavy doors and cold environments.

- Whale Tail Latch: The large, paddle-style handle is designed to be easily grasped and operated with a gloved hand. The rotation and pull required to open the latch are combined into a single, intuitive motion. Furthermore, the latch provides a clear tactile and visual cue (the handle position) regarding the door status (locked or unlocked, latched or unlatched).

- Cam Lock: The Cam Lock, in its simplest form, offers no inherent handle. Operation requires the use of the key to turn the cam and then a separate pull (using a small handle or the lock cylinder itself) to open the door. This two-step, multi-component action is less convenient and often requires more dexterity.

6.2 Keying Options and Master Key Systems

The flexibility in key management is a critical factor for large fleets or complex industrial facilities.

- Keyed Alike (KA) vs. Keyed Different (KD): Both lock types are available as Keyed Alike (one key for all locks in a fleet) or Keyed Different (unique key for each lock). However, the customization of keying for Cam Locks is often more prevalent and simpler to manage due to their standardized cylinder size.

- Master Key Systems: Implementing a complex master key system—where a single key opens all locks while individual keys only open specific locks—is achievable for both. For industrial OEM applications, working with a reputable manufacturer like ESM ensures the required keying hierarchy is established from the design phase.

6.3 Effort of Closure and Vibration Dampening

The mechanism of closure impacts both user effort and long-term compartment integrity.

Because the Whale Tail is a compression latch, it requires a higher closing force to engage the final compression stroke. While this effort is necessary to achieve the high seal and anti-vibration qualities, some operators may perceive it as harder to close than a simple Cam Lock system. The Cam Lock requires minimal force; it merely prevents rotation of the cam, relying on external buffers to dampen vibration and rattling.

Cost Analysis and Long-Term Return on Investment (ROI)

For high-volume production and industrial purchasing, the total cost of ownership (TCO) is more critical than the initial unit price. The investment in a lock mechanism must be weighed against its lifecycle benefits, including maintenance and failure rates.

7.1 Initial Unit Cost and Complexity

The unit price differential is a direct result of the lock's mechanical complexity and material requirements.

- Cam Lock (Low Initial Cost): Standard Cam Locks are mass-produced components with minimal material and simple design. They consistently offer the lowest unit price, making them attractive for non-critical, internal, or low-exposure applications.

- Whale Tail Latch (Higher Initial Cost): The Whale Tail latch is a complex assembly that includes multiple moving parts, heavy-duty handle components, and potentially an internal rod system. This necessitates more material (often higher-grade alloys) and sophisticated manufacturing processes (e.g., precision casting and machining). Therefore, the initial unit cost is substantially higher.

7.2 Total Cost of Ownership (TCO)

TCO accounts for all costs over the lifespan, including initial purchase, installation, and maintenance.

| Cost Factor | Whale Tail Latch | Standard Cam Lock |

|---|---|---|

| Installation Labor | Higher; requires precise, larger cutout and multi-point adjustment. | Lower; quick, simple drill-and-mount installation. |

| Maintenance/Replacement | Lower; superior sealing reduces internal equipment damage and failure rates. Robustness leads to fewer mechanical failures. | Higher; increased risk of failure due to rattling, lower resistance to corrosion, and poor sealing leads to weather-related damage inside the compartment. |

| Associated Costs | Lower risk of inventory loss or damage due to high security and superior seal. | Higher risk of theft-related losses or internal tool damage due to water/dust ingress. |

7.3 Return on Investment (ROI) Justification

The justification for the higher investment in a Whale Tail latch is found in long-term performance and risk mitigation:

For high-value equipment or fleet operations exposed to severe weather (rain, dust, road salt), the superior sealing and enhanced security of the Whale Tail translates into a quantifiable ROI through:

- Reduced cargo/equipment loss (lower insurance claims).

- Extended lifespan of internal electronics and tools (reduced replacement costs).

- Minimal door rattling, which reduces component stress and premature wear on the vehicle body.

For applications where the compartment contents are low-value and environmental exposure is minimal, the lower TCO of the standard Cam Lock often provides a better economic return.

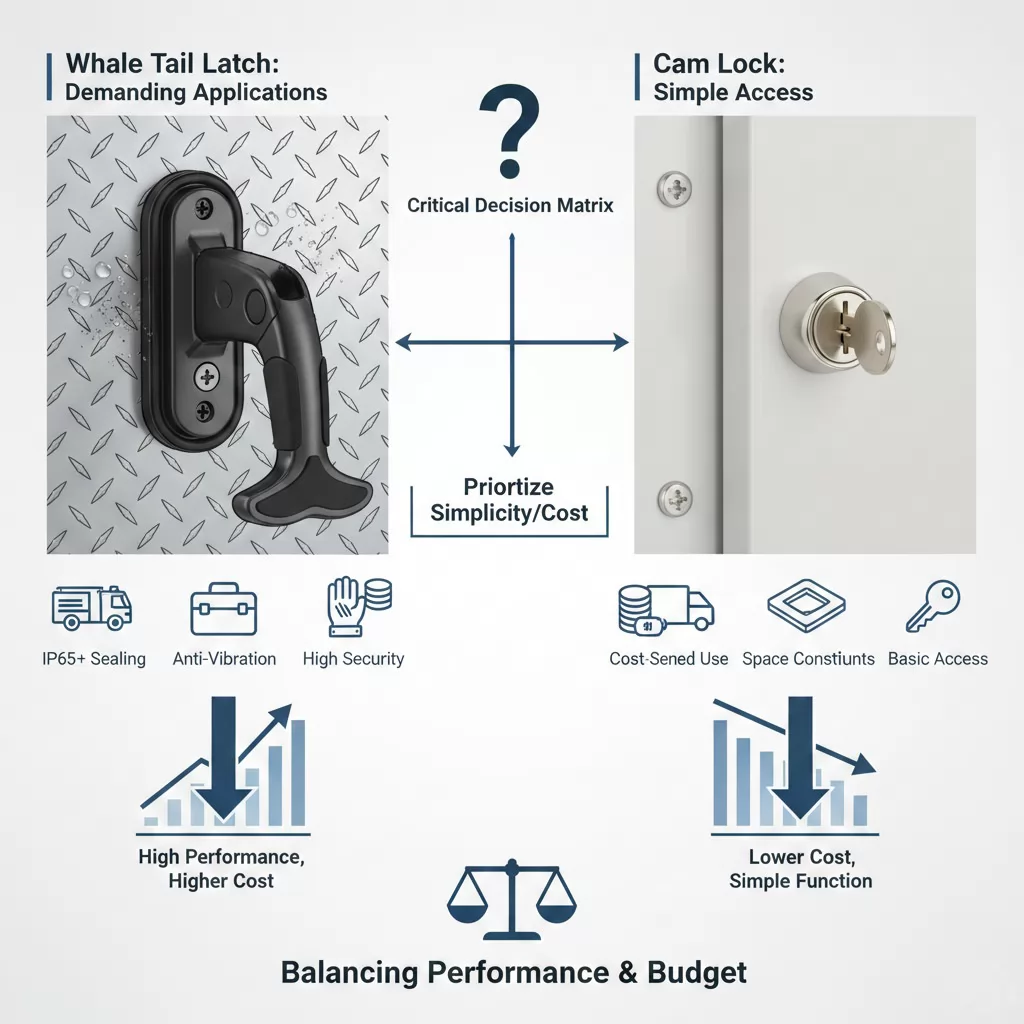

Selecting the Right Mechanism: Application-Specific Criteria

The choice between a Whale Tail latch and a Cam Lock is not about superiority, but about aligning the lock's characteristics with the specific operational and environmental requirements of the application. Engineers must define the necessary performance envelope before specifying the hardware.

8.1 Critical Decision Matrix: Whale Tail Suitability

The Whale Tail compression latch is the optimal choice when the following criteria are met:

- Sealing and Weatherproofing: The application requires an IP rating of IP65 or higher (e.g., exposed fire trucks, utility vehicles, or remote mining equipment). The compression feature is non-negotiable for dust and water resistance.

- Anti-Vibration Performance: The compartment is mounted on a dynamically stressed vehicle and requires complete elimination of door rattle and component movement during transport.

- Security Priority: The compartment stores high-value tools, sensitive electronics, or is frequently left unattended in high-risk areas. The multi-point locking offers enhanced resistance to prying.

- Ergonomics: The user needs a large, easy-to-use handle that can be operated quickly, potentially with heavy gloves, or in poor visibility conditions.

8.2 Critical Decision Matrix: Cam Lock Suitability

The standard Cam Lock is the preferred solution when the application prioritizes simplicity, cost, and compact size:

- Cost Sensitivity: High-volume production where initial hardware cost is the primary factor, and the contents are of lower value.

- Internal or Protected Use: The compartment is located inside a larger enclosure or is protected from direct, severe environmental exposure (e.g., inside a van body, internal electrical panels).

- Space Constraints: When the depth behind the panel is extremely limited, the shallow profile of the Cam Lock is advantageous.

- Simple Access Control: The primary need is basic key-controlled access, and the high-level security/compression sealing of a Whale Tail is considered over-engineered for the task.

Conclusion: Balancing Performance and Budget

In summary, the Whale Tail latch is an integrated, high-performance latching and locking system designed to manage demanding operational stresses, offering superior security, sealing, and vibration damping at a premium. The Cam Lock is a simple, cost-effective, discrete locking cylinder suitable for less demanding applications focused primarily on basic access restriction.

Procurement decisions should reflect a clear alignment between the lock mechanism's capabilities (robustness, IP rating) and the projected lifecycle demands of the industrial application.

About Ningbo East Sea Machinery (ESM): Your Precision Hardware Partner

Ningbo East Sea Machinery Co., Ltd (ESM) was established in 2002 and has built a 20-year legacy specializing in precision-engineered hardware solutions for commercial vehicles, trailers, special vehicles, and industrial enclosures. Our focus areas include heavy-duty door locks, latches, hinges, folding steps, and handles.

Operating from an 8,000 m² ISO9001-certified facility in Ningbo, China, we manage integrated production processes covering casting, stamping, forging, CNC machining, and sheet metal fabrication. We are committed to delivering components that ensure superior durability and performance in the most demanding environments globally, serving key partners in the USA, Canada, Australia, and European markets.

Why Choose ESM for Heavy-Duty Locks?

- Certified OEM Quality: ISO9001 certification ensures rigorous quality systems and consistency across all 10M+ OEM units delivered.

- Integrated Manufacturing Capability: Full-scope production from raw material processes to finished CNC parts allows for exceptional quality control and rapid response.

- Global Reliability: Trusted supplier to demanding overseas customers, guaranteeing proven reliability in heavy-duty applications.

- Custom R&D Support: Our engineers actively collaborate with clients from concept to production, optimizing structural design for superior usability and cost-effectiveness.

Contact Our Engineering Team

Selecting the optimal locking mechanism requires precise alignment with your application’s environment and usage cycle. Whether you require the extreme sealing of a Whale Tail compression latch or the robust simplicity of a heavy-duty Cam Lock, ESM offers customizable solutions.

Contact our engineering and sales team today to discuss your project specifications, request detailed CAD drawings, and explore how our custom R&D capabilities can optimize the security and lifespan of your commercial vehicle components.

Explore our industrial hardware solutions at East Sea Machinery

-

Jul 16, 2025What Are the Different Types of Toolbox Locks?(Comprehensive Guide)

Jul 16, 2025What Are the Different Types of Toolbox Locks?(Comprehensive Guide) -

Sep 18, 2025Top 10 Most Popular Pickup Truck Models in the Americas in 2025

Sep 18, 2025Top 10 Most Popular Pickup Truck Models in the Americas in 2025 -

Sep 11, 2025Top 10 Truck Tool Box Lock Manufacturers in the World

Sep 11, 2025Top 10 Truck Tool Box Lock Manufacturers in the World -

Sep 30, 2025Top 10 Most Common Special Purpose Vehicles in North America

Sep 30, 2025Top 10 Most Common Special Purpose Vehicles in North America