Lock Dust Cover Explained: How They Protect Your Truck Storage

_1757411559_WNo_1600d900.webp)

Table of Contents

- Why Lock Dust Covers are Essential for Truck Body Security

- Common Threats to Truck Locks: Moisture, Road Dust, and Debris

- The Mechanism of Folding T-Handle Locks with Waterproof Caps

- Material Synergy: 304 Stainless Steel and Industrial Rubber Covers

- Understanding Ingress Protection: How Waterproof Covers Prevent Failure

- Ideal Applications for Dust-Proof Locking Hardware in Heavy-Duty Vehicles

- Key Factors When Selecting Locks with Protective Covers for OEM Manufacturing

Why Lock Dust Covers are Essential for Truck Body Security

For heavy-duty industrial vehicles, the integrity of storage compartments relies heavily on the durability of the locking mechanism. A Lock Dust Cover is not merely an accessory; it is a critical component designed to shield the internal cylinder from environmental aggression.

Truck bodies, service vehicles, and utility toolboxes operate in uncontrolled environments where exposure to contaminants is inevitable. Without a proper Lock Waterproof Cover, the precision components inside a lock cylinder are vulnerable to seizing, corrosion, and mechanical failure. This section explores why integrating protective covers is standard practice for ensuring long-term security and reducing maintenance costs for fleet operators.

- Prevents Debris Ingress: Blocks road grime, sand, and metallic dust from entering the keyway.

- Reduces Corrosion Risk: Acts as a primary barrier against moisture and de-icing salts.

- Extends Cycle Life: Ensures smooth key insertion and rotation over thousands of operation cycles.

Common Threats to Truck Locks: Moisture, Road Dust, and Debris

_1757412054_WNo_1706d1279.webp)

Industrial vehicles travel through diverse and often harsh terrains, exposing their external hardware to severe environmental stressors. The lock cylinder is particularly susceptible because it contains small, precision-machined parts that require tight tolerances to function correctly. Without the shielding provided by a Lock Dust Cover, these components face immediate degradation.

One of the primary enemies is moisture accumulation. Rain, humidity, and high-pressure car washes can force water into the keyway. In colder climates, this trapped water can freeze, rendering the lock inoperable until thawed. Furthermore, for vehicles operating in coastal areas or winter roads treated with salt, the combination of moisture and salinity accelerates galvanic corrosion, causing the internal pins and springs to seize permanently.

Abrasive road dust poses a different but equally destructive threat. Fine particles of sand, dirt, and brake dust can infiltrate the mechanism. Over time, these particles act like sandpaper inside the cylinder, wearing down the brass or stainless steel components. This friction eventually leads to key sticking or total mechanical failure.

- Internal Corrosion: Caused by chemical reactions from salt spray and water retention.

- Mechanical Jamming: Resulting from the buildup of particulate matter in the tumbler.

- Freeze-Up: Occurs when trapped water turns to ice, blocking key insertion.

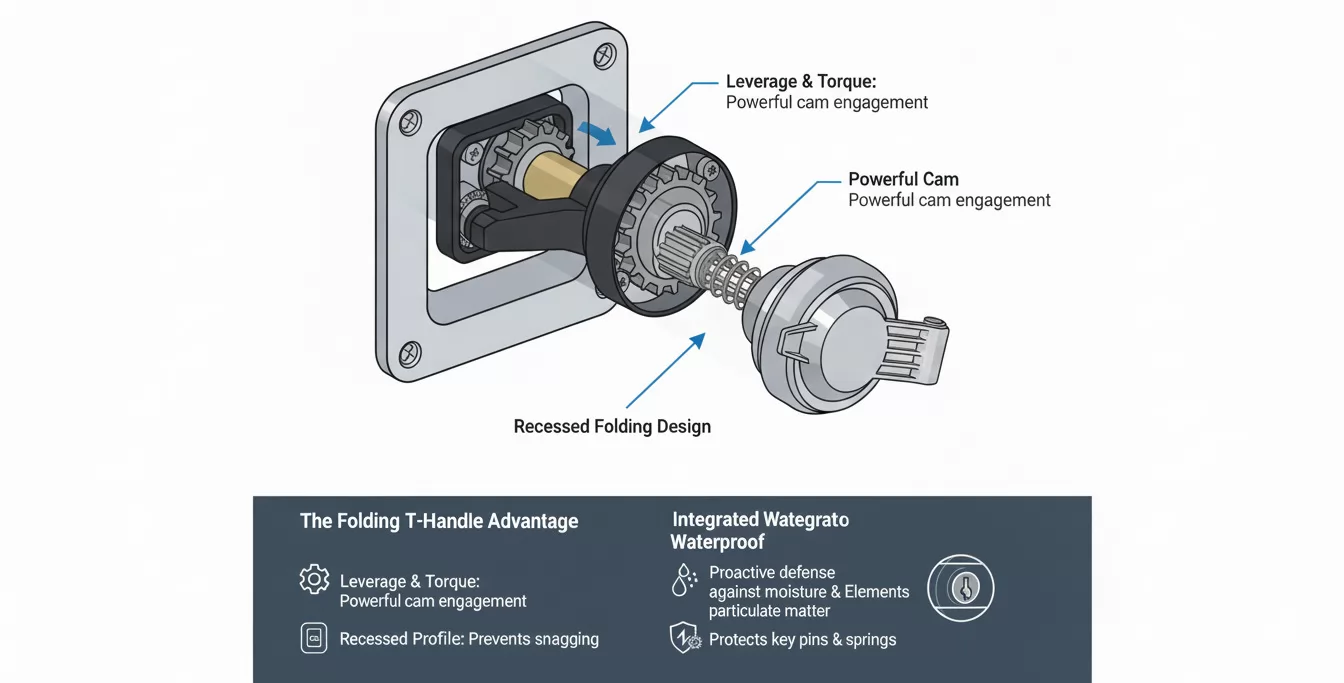

The Mechanism of Folding T-Handle Locks with Waterproof Caps

The Folding T-Handle Lock represents a significant design evolution in industrial hardware, combining robust locking security with ergonomic operation. This mechanism is intrinsically durable, but its longevity is maximized only when coupled with a dedicated Lock Waterproof Cover.

The Folding T-Handle Advantage

The core advantage of the T-handle design is the leverage it provides for securing multi-point latching systems common in truck bodies. Once rotated and secured, the handle allows for a positive, firm seal on the compartment door. The "folding" characteristic is crucial for safety and installation profile, allowing the handle to recess or fold flat when locked, preventing snag hazards and minimizing overall protrusion from the vehicle body.

- Leverage and Torque: Allows for powerful cam engagement, ensuring doors remain closed under vibration.

- Recessed Profile: Reduces the risk of accidental damage or snagging on operational clothing/equipment.

Function of the Integrated Waterproof Seal

The Waterproof Cap is the proactive defense mechanism. Typically constructed from industrial-grade rubber or elastomer, the cap is designed to fit snugly over the lock cylinder face. Its function is to create a physical, static barrier that completely covers the keyway entrance. When closed, this barrier prevents particulate matter and moisture from settling on the key pins and springs, which are the most susceptible components to environmental decay. Effective caps often feature an internal lip or tight tolerance fit to ensure reliable sealing under constant vibration.

Material Synergy: 304 Stainless Steel and Industrial Rubber Covers

The foundation of a reliable external lock system is the appropriate selection of materials. For extreme environments, the synergy between the lock body's metal and the cover's elastomer dictates the long-term performance and lifespan of the entire unit. This pairing is crucial for ensuring the lock provides years of service without seizing.

The Advantage of 304 Stainless Steel

304 Stainless Steel is the industry standard for high-exposure hardware due to its inherent resistance to oxidation and corrosion. This superior protection stems from the minimum $18%$ chromium content, which reacts with oxygen to form a thin, durable passive layer on the surface. While the exterior housing is protected, the tight mechanical tolerances of the internal key cylinder, springs, and pins still require dedicated defense against fine particulates and moisture.

- Offers excellent resistance to general corrosion and common environmental acids.

- Provides a clean, highly polished finish (as per the client's product) that resists tarnishing.

The Role of the Cover Material

The Lock Waterproof Cover acts as the crucial secondary barrier. Typically manufactured from UV-stabilized industrial rubber or high-grade elastomer, the cover ensures that the most vulnerable area—the keyway—is sealed. This material must possess specific characteristics:

- Flexibility: Must remain pliable across wide temperature fluctuations to maintain a watertight seal.

- UV Stability: Resists cracking and degradation from continuous solar exposure.

- Chemical Resistance: Able to withstand exposure to road oils, cleaning solvents, and de-icing chemicals.

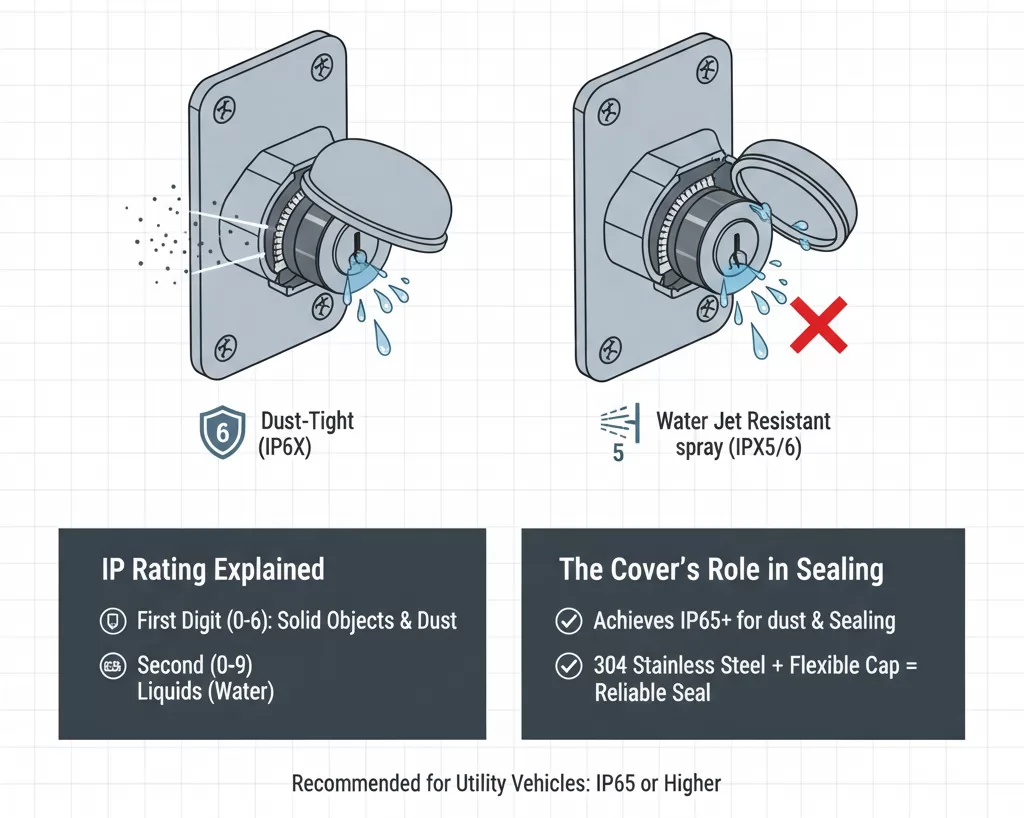

Understanding Ingress Protection: How Waterproof Covers Prevent Failure

For B2B procurement and engineering teams, the durability of hardware must be quantifiable. This is achieved through the Ingress Protection (IP) rating, a standard defined by the International Electrotechnical Commission (IEC 60529). This rating formally quantifies a lock's resistance to intrusion by foreign bodies, specifically particulate matter and moisture.

IP Rating Explained

The two-digit IP code provides clear specifications:

- First Digit (0-6): Protection level against solid objects and dust. A rating of 6 means the enclosure is dust-tight—no ingress of dust under vacuum pressure.

- Second Digit (0-9): Protection level against liquids (water). Ratings range from simple dripping water (IPX1) to resistance against powerful water jets (IPX6) or continuous immersion (IPX7/X8).

The Cover's Role in Achieving Sealing

The presence of a well-designed Lock Waterproof Cover is instrumental in helping the assembly achieve critical IP standards, particularly the high scores required for dust-tightness (IP6X) and resistance to direct spray (IPX5/X6). While the 304 Stainless Steel body provides structural integrity, the flexible cap is the only component capable of creating a temporary, high-tolerance seal over the dynamic keyway opening, preventing ingress that would otherwise compromise the lock’s internal mechanism.

For external hardware on utility vehicles, specifying an IP rating of IP65 or higher is generally recommended to ensure reliable operation in all weather conditions.

Ideal Applications for Dust-Proof Locking Hardware in Heavy-Duty Vehicles

The specialized construction of a Lock Waterproof Cover combined with the robust housing of a 304 Stainless Steel lock assembly is engineered for environments where standard hardware fails. Procurement specialists should target this dust-proof locking hardware for mission-critical applications where compartment security and operational reliability cannot be compromised by weather or contamination.

Key Industry Applications

The following industries benefit significantly from specifying sealed locking solutions for their external storage compartments:

- Utility and Service Trucks: Vehicles used by telecom, electric, and plumbing services require compartments that keep sensitive tools and spare parts dry and protected in all weather for immediate access during field maintenance.

- Construction and Mining Equipment: These sites are characterized by high levels of abrasive dust, mud, and continuous vibration. The sealing capacity is critical for maintaining the lock mechanism's longevity.

- Emergency and Fire Apparatus: The reliability of access is paramount. Locks must operate instantly regardless of rain, snow, or heat, making the integrated protective cover an essential feature.

- Commercial Transportation Trailers: Locks on external toolboxes, battery compartments, and access panels benefit from the enhanced security and reduced maintenance costs provided by fully sealed units.

Key Factors When Selecting Locks with Protective Covers for OEM Manufacturing

For OEM manufacturing, the selection of external hardware dictates the overall quality and long-term cost of ownership (LCOO) for the end product. Poorly specified Lock Dust Cover assemblies can lead to frequent warranty claims. Procurement decisions must therefore be based on verifiable technical specifications and manufacturing quality.

Critical Technical Specifications

Buyers must rigorously verify the following specifications beyond aesthetic appearance:

- Material Certification: Require proof of compliance for the 304 Stainless Steel alloy used in the lock body, ensuring the specified $18%$ chromium content for adequate corrosion resistance.

- IP Rating Verification: Confirm the supplier can provide testing data supporting the claimed Ingress Protection (IP) rating for the lock and cover assembly, particularly resistance to high-pressure water spray (IPX5/6).

- Operating Temperature Range: Ensure the industrial rubber used in the Lock Waterproof Cover remains functional and seals effectively in the full temperature range of the intended operating environment.

Manufacturing and Design Fit

The lock must integrate seamlessly into the vehicle design without requiring custom modification:

- Installation Footprint: Verify precise dimensional drawings to ensure compatibility with existing or planned body panel cutouts for efficient assembly line integration.

- Finish Quality: Assess the surface treatment, such as the polishing finish, for consistency and resistance to pitting, which is often a precursor to corrosion.

- Cycle Testing: Demand evidence of physical durability testing (e.g., 50,000+ opening/closing cycles) to guarantee the lock mechanism and the cover’s hinge/attachment point will withstand prolonged use.

The Eastsea Advantage: Two Decades of Trusted Innovation

What sets Eastsea Machinery apart isn’t just our product catalog — it’s our philosophy.

We don’t design locks in a lab. We design them on job sites, in fleet yards, and alongside our customers. Every curve of the T-handle, every micron of gasket thickness, every polish on the steel surface — it’s all informed by feedback from people who use these locks every day.

Our certifications aren’t framed for the wall — they’re benchmarks we live by. Our customization capabilities aren’t marketing fluff — they’re solutions for unique mounting configurations, keying systems, or environmental challenges.

Whether you’re outfitting a single work truck or an entire national fleet, we provide more than hardware — we provide peace of mind.

Final Word: Don’t Wait for Damage to Happen — Prevent It

The cost of a high-quality waterproof cap lock is negligible compared to the value of what it protects. A single rusted impact wrench, a corroded battery, or a seized lock during an emergency can cost far more — in money, time, and opportunity — than the price of prevention.

At Eastsea Machinery, we believe your tools deserve better than “good enough.” They deserve engineered protection — built to last, designed for the elements, and backed by two decades of expertise.

-

Jul 16, 2025What Are the Different Types of Toolbox Locks?(Comprehensive Guide)

Jul 16, 2025What Are the Different Types of Toolbox Locks?(Comprehensive Guide) -

Sep 18, 2025Top 10 Most Popular Pickup Truck Models in the Americas in 2025

Sep 18, 2025Top 10 Most Popular Pickup Truck Models in the Americas in 2025 -

Sep 11, 2025Top 10 Truck Tool Box Lock Manufacturers in the World

Sep 11, 2025Top 10 Truck Tool Box Lock Manufacturers in the World -

Sep 30, 2025Top 10 Most Common Special Purpose Vehicles in North America

Sep 30, 2025Top 10 Most Common Special Purpose Vehicles in North America