Top 10 Reasons Your Truck Tool Box Needs a Heavy-Duty Lock

For commercial truck operators, utility fleets, and heavy machinery professionals, a truck tool box is more than just storage—it is a mobile warehouse housing thousands of dollars in critical equipment. Whether you are transporting hydraulic tools, diagnostic devices, or essential repair kits, the integrity of your operation often hinges on the security of these assets. However, the tool box is only as secure as its weakest link: the locking mechanism.

In the industrial sector, standard consumer-grade latches often fail to meet the demands of the road. They succumb to corrosion, vibrate loose during transit, or offer little resistance to forced entry. Investing in heavy-duty locks—such as stainless steel paddle latches, compression T-handles, or cam locks designed for industrial use—is not merely an upgrade; it is a necessity for risk management. This guide outlines the top ten technical and operational reasons why your fleet requires industrial-grade locking hardware to protect your bottom line.

Table of Contents

- Reason 1: Preventing Theft of High-Value Industrial Tools

- Reason 2: Withstanding Harsh Weather and Environmental Corrosion

- Reason 3: Resisting Vibration and Shock During Transit

- Reason 4: Preventing Accidental Latch Release on the Road

- Reason 5: Superior Resistance to Physical Tampering and Drilling

- Reason 6: Reducing Long-Term Maintenance and Replacement Costs

- Reason 7: Ensuring Operational Efficiency with Reliable Mechanism

- Reason 8: Compliance with Fleet Insurance and Safety Standards

- Reason 9: Enhancing Professional Image and Reliability

- Reason 10: Extended Service Life in Heavy-Duty Applications

- Conclusion: Investing in Quality Hardware for Maximum Protection

Reason 1: Preventing Theft of High-Value Industrial Tools

Commercial trucks often carry specialized equipment ranging from heavy-duty pneumatic wrenches to precision diagnostic computers. The loss of these assets results in immediate financial strain, but the consequential cost of operational downtime often exceeds the replacement value of the tools themselves. If a technician arrives at a job site without the necessary equipment due to theft, the project halts, and professional reputation suffers.

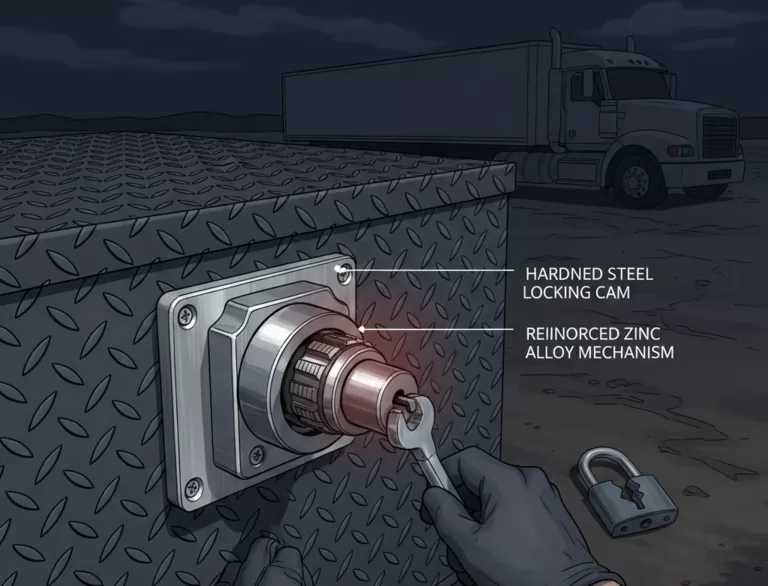

Standard residential-grade latches often utilize simple wafer tumblers or weak pawls that can be easily bypassed by shimming or forced open with basic leverage. In contrast, heavy-duty truck tool box locks are engineered to withstand substantial brute force. Features such as hardened steel locking cams, reinforced housings (often made from stainless steel or zinc alloy), and complex cylinder designs significantly increase the time and effort required for unauthorized access. By installing high-security industrial latches, you transform your storage units from easy targets into hardened vaults, effectively deterring opportunistic theft in unsecured parking lots or remote job sites.

Reason 2: Withstanding Harsh Weather and Environmental Corrosion

Commercial trucks, unlike personal vehicles, operate in some of the most punishing environmental conditions imaginable. From scorching highways to freezing northern routes laden with de-icing salts, the exterior hardware of a truck is under constant attack. Standard locks often feature components made of mild steel or low-grade alloys that inevitably succumb to rust and oxidation. A corroded lock is not just an aesthetic issue; it is a functional failure that can seize up completely, leaving critical tools trapped inside the box when they are needed most.

Heavy-duty locks are specifically manufactured to resist these environmental stressors. High-quality industrial latches typically utilize 304 or 316 grade stainless steel for the pan, handle, and internal mechanism. These materials provide superior resistance to rust, even when exposed to moisture, road grime, and corrosive chemical agents like magnesium chloride used on winter roads. Additionally, heavy-duty designs often incorporate weather-resistant finishes—such as black powder coating or chrome plating—and are equipped with rubber gaskets or internal O-rings. These seals prevent water and dust ingress (often rated to IP standards), protecting the internal cylinder and springs from freezing or clogging, thereby ensuring consistent operation regardless of the weather.

Reason 3: Resisting Vibration and Shock During Transit

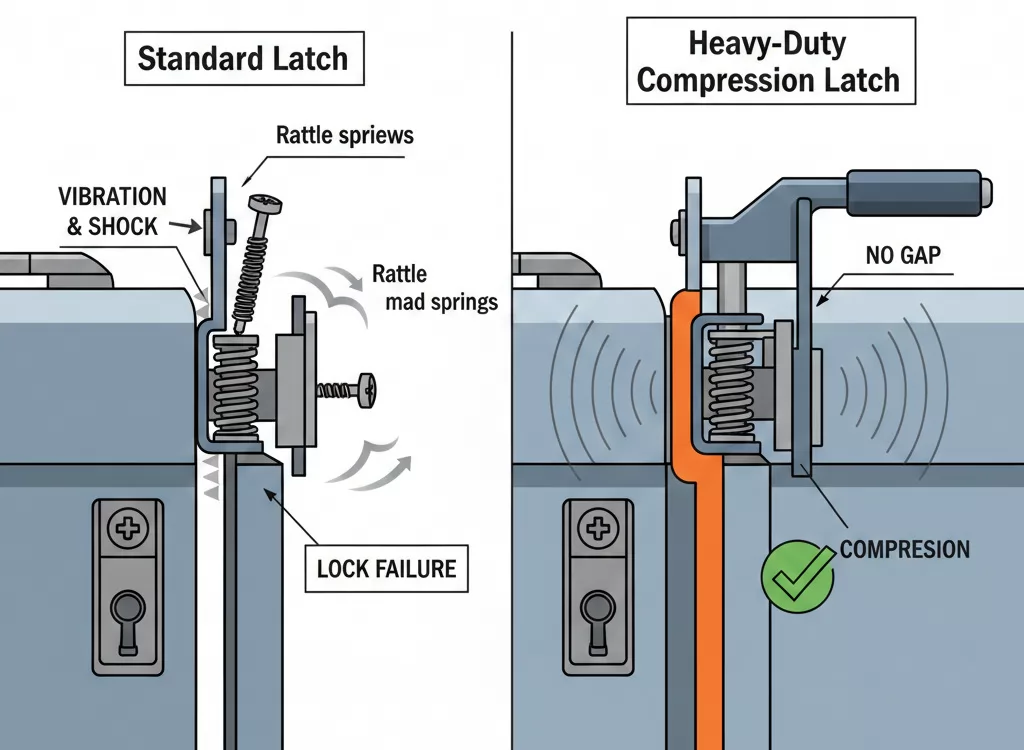

The dynamic environment of heavy-duty trucking subjects every component of the vehicle to continuous vibration and high-impact shock. Whether driving over uneven construction site terrain or enduring the high-frequency vibrations of highway travel, tool box latches face constant mechanical stress. Standard locking mechanisms typically lack the structural integrity to handle this "dynamic loading." Over time, vibration causes internal pins to wear down, screws to back out, and springs to fatigue, eventually causing the lock to fail or the latch to rattle incessantly.

Heavy-duty locks are engineered with vibration resistance as a core design criteria. Many industrial-grade options, particularly compression latches, are designed to pull the tool box door tightly against the frame gasket. This compression eliminates the "play" or gap between the door and the box, effectively dampening vibration and preventing the hardware from rattling. Furthermore, heavy-duty mechanisms utilize robust internal springs and reinforced pawls that maintain their engagement even under sudden shock loads, such as hitting a pothole or traversing off-road tracks. This ensures that the structural integrity of the lock remains intact, preventing metal fatigue and ensuring the door stays securely shut mile after mile.

Reason 4: Preventing Accidental Latch Release on the Road

One of the most severe risks for any fleet operator is a tool box door swinging open while the vehicle is in motion. This not only results in the catastrophic loss of expensive tools spilling onto the highway but poses a significant safety hazard to other motorists, leading to potential accidents and substantial liability claims. Standard cam locks or simple single-point latches often rely on precise alignment to stay closed. However, truck chassis are designed to flex and twist during operation; this structural movement can cause rigid, lower-quality latches to disengage unexpectedly.

Heavy-duty locking systems address this issue through superior mechanical design. Compression latches and rotary paddle latches are particularly effective in this regard. A compression latch allows the user to tighten the door against the seal, accommodating chassis flex without losing grip. Similarly, heavy-duty rotary latches often feature a "two-stage" or double-bit locking mechanism—similar to a car door—which ensures that even if the primary latch position is compromised by severe twisting or vibration, the secondary catch prevents the door from flying open. By upgrading to hardware that offers positive locking engagement, operators eliminate the risk of accidental release, ensuring safety for both the cargo and the public.

Reason 5: Superior Resistance to Physical Tampering and Drilling

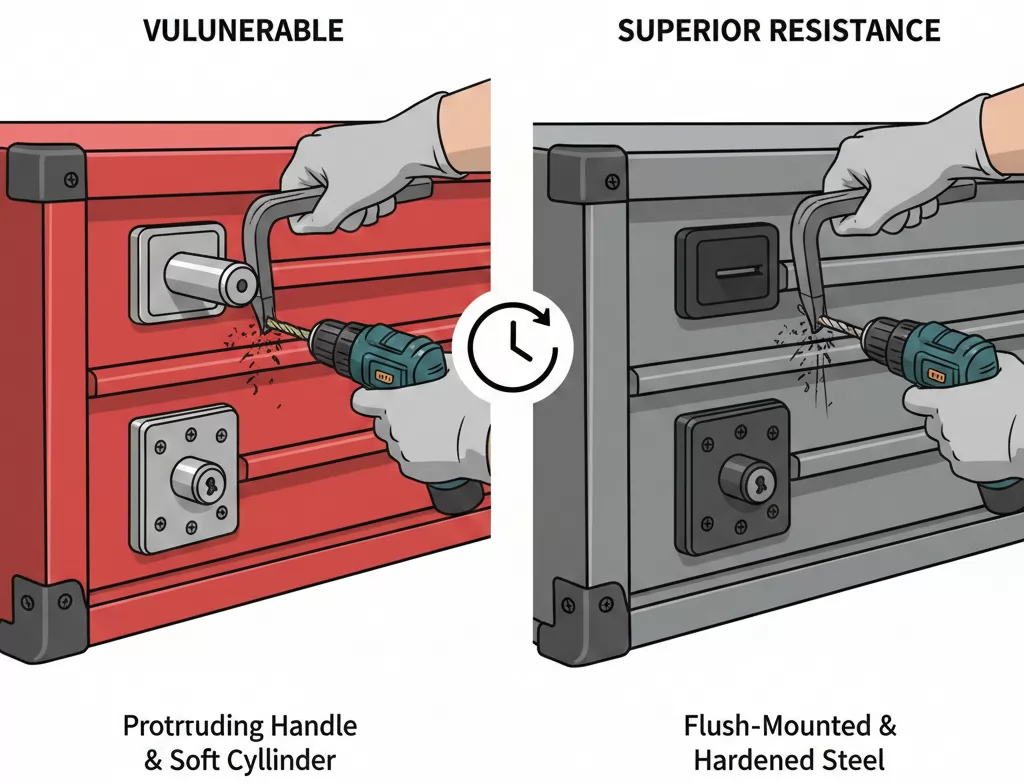

Security is often a function of time; the longer it takes to bypass a lock, the more likely a thief is to abandon the attempt. Standard tool box locks often feature protruding handles or weak zinc die-cast cylinders that are vulnerable to common physical attacks. A simple pry bar can easily snap a protruding T-handle, while a standard drill bit can quickly destroy a soft metal cylinder core, rendering the locking mechanism useless in seconds.

Heavy-duty industrial locks are engineered with anti-tamper features designed to frustrate and withstand these aggressive entry methods. Flush-mounted paddle handles are a prime example; their recessed design sits flush with the tool box surface, leaving no leverage points for a crowbar or pry tool to grip. Internally, high-security locks often utilize hardened steel pins or plates within the cylinder to deflect drill bits. Furthermore, the housing bodies are typically constructed from investment-cast stainless steel or heavy-gauge reinforced materials that resist impact damage. Some advanced heavy-duty models also feature shrouded shackles or concealed mounting studs, ensuring that the lock cannot be unscrewed or dismantled from the outside.

Reason 6: Reducing Long-Term Maintenance and Replacement Costs

In fleet management and industrial operations, procurement decisions are often driven by the Total Cost of Ownership (TCO) rather than the initial purchase price. While standard, economy-grade locks may appear cost-effective upfront, they frequently become a recurring financial drain. Low-quality latches wear out quickly under daily industrial use—keys snap off in jammed cylinders, internal springs fail, and rusted mechanisms require constant lubrication or complete replacement. Every time a lock fails, it incurs not just the cost of the new part, but also the labor cost of removal and installation, and potentially valuable vehicle downtime.

Heavy-duty locks are built to endure rigorous duty cycles, often rated for tens of thousands of actuations. Their robust construction minimizes the need for frequent maintenance. For instance, a polished stainless steel paddle latch with a high-quality internal mechanism requires little more than occasional cleaning to maintain peak performance over years of service. By investing in premium hardware, companies significantly extend the replacement intervals of their components. This "fit and forget" reliability translates to lower maintenance overheads and ensures that maintenance teams can focus on critical vehicle mechanics rather than replacing broken door handles.

_1763952605_WNo_1024d1024.webp)

Reason 7: Ensuring Operational Efficiency with Reliable Mechanism

Time is a critical resource in the logistics and construction industries. When a technician or driver needs access to a specific tool to perform a roadside repair or complete a job site task, every second counts. A low-quality lock that jams, sticks, or requires excessive jiggling to open is not just an annoyance—it is a friction point in the workflow. In cold weather or dirty environments, a seized lock can cause significant delays, frustrating personnel and potentially halting operations.

Heavy-duty locking mechanisms are designed with precision engineering to ensure smooth, consistent actuation every time. Unlike budget options that may use rough-cast internal components, premium industrial locks feature machined parts with tighter tolerances and smoother surfaces. This results in a crisp "open and close" feel that does not degrade easily over time. Furthermore, heavy-duty designs often prioritize ergonomics; large folding T-handles or wide paddle latches are specifically shaped to be easily operated even while wearing thick work gloves. This user-centric design ensures that access to equipment is seamless and instant, maintaining high productivity levels for the workforce.

Reason 8: Compliance with Fleet Insurance and Safety Standards

In the commercial sector, managing risk and liability is paramount. Fleet insurance underwriters assess security measures when determining coverage eligibility and premium rates, particularly when valuable specialized tools are part of the insured assets. Installing demonstrably heavy-duty, high-security locks signals a commitment to asset protection and risk mitigation, which can lead to more favorable insurance terms or ensure compliance with existing policy requirements for high-risk equipment.

Beyond property insurance, heavy-duty locks are crucial for safety compliance. As discussed previously (Reason 4), an accidentally opened tool box is a road hazard. Regulatory agencies and internal safety protocols demand that all unsecured items are contained. By utilizing certified industrial-grade hardware, companies fulfill their due diligence requirement to prevent cargo loss and potential public safety incidents. Furthermore, reputable heavy-duty lock manufacturers provide detailed material specifications and durability ratings that satisfy the documentation requirements often necessary for procurement and internal safety audits.

Reason 9: Enhancing Professional Image and Reliability

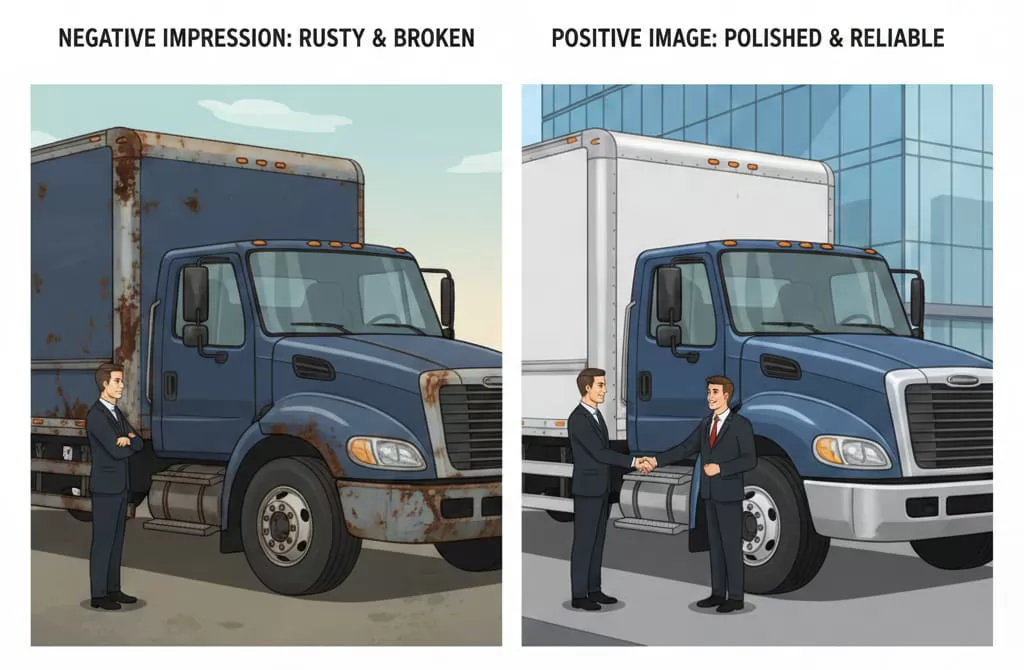

In the business-to-business (B2B) sector, a commercial vehicle is often the first physical representation of a company seen by a client or partner. A truck with rusty, mismatched, or broken tool box hardware—specifically a failing latch—can negatively impact brand perception. It suggests a lack of attention to detail and an unwillingness to invest in quality, potentially leading prospective clients to question the quality control of the company’s core services.

Heavy-duty locks, particularly those manufactured from highly finished materials like polished stainless steel, maintain a clean, professional aesthetic over years of use, even in harsh conditions. Their solid construction and flawless operation project an image of competency, reliability, and investment. When every component on a fleet vehicle, down to the securing mechanism, reflects premium quality, it reinforces the company’s overall reliability and commitment to asset management, thus building stronger client confidence.

Reason 10: Extended Service Life in Heavy-Duty Applications

The cumulative benefit of all the preceding technical features—superior material grade, precision manufacturing, and robust design—is a dramatically extended service life. In the demanding environment of commercial vehicle operation, "heavy-duty" means a predictable and sustained performance across many years, far exceeding the lifespan of standard hardware.

Low-cost locks are often manufactured with thin-gauge components, leading to accelerated fatigue failure in springs, cams, and pawls. In contrast, industrial-grade locks are often built with thicker metal castings and robust internal linkages designed to resist continuous friction and wear. Investing in hardware certified for long-term use ensures that the lock remains functionally secure and mechanically smooth throughout the entire operational life of the truck, potentially lasting over a decade. For fleet owners and procurement teams, this longevity minimizes lifecycle costs and makes capital expenditure planning more predictable by eliminating the need for frequent, unscheduled component replacements.

Conclusion: Investing in Quality Hardware for Maximum Protection

The decision to equip a commercial vehicle with a heavy-duty lock system is a strategic choice that extends far beyond simple anti-theft measures. As demonstrated by these ten essential reasons, industrial-grade locking hardware is foundational to the operational integrity of any working truck.

By resisting the dual threats of theft and environmental degradation, high-quality stainless steel or robust alloy latches minimize vehicle downtime, significantly lower the Total Cost of Ownership (TCO), and ensure regulatory compliance. For fleet managers and purchasing professionals, investing in a durable, reliable lock mechanism is an investment in asset protection, workforce efficiency, and the long-term professional reputation of the company. Ultimately, securing your high-value tools with precision-engineered hardware is the clearest path to maximizing operational uptime and safeguarding your capital assets in the field.

-

Jul 16, 2025What Are the Different Types of Toolbox Locks?(Comprehensive Guide)

Jul 16, 2025What Are the Different Types of Toolbox Locks?(Comprehensive Guide) -

Sep 18, 2025Top 10 Most Popular Pickup Truck Models in the Americas in 2025

Sep 18, 2025Top 10 Most Popular Pickup Truck Models in the Americas in 2025 -

Sep 11, 2025Top 10 Truck Tool Box Lock Manufacturers in the World

Sep 11, 2025Top 10 Truck Tool Box Lock Manufacturers in the World -

Sep 30, 2025Top 10 Most Common Special Purpose Vehicles in North America

Sep 30, 2025Top 10 Most Common Special Purpose Vehicles in North America