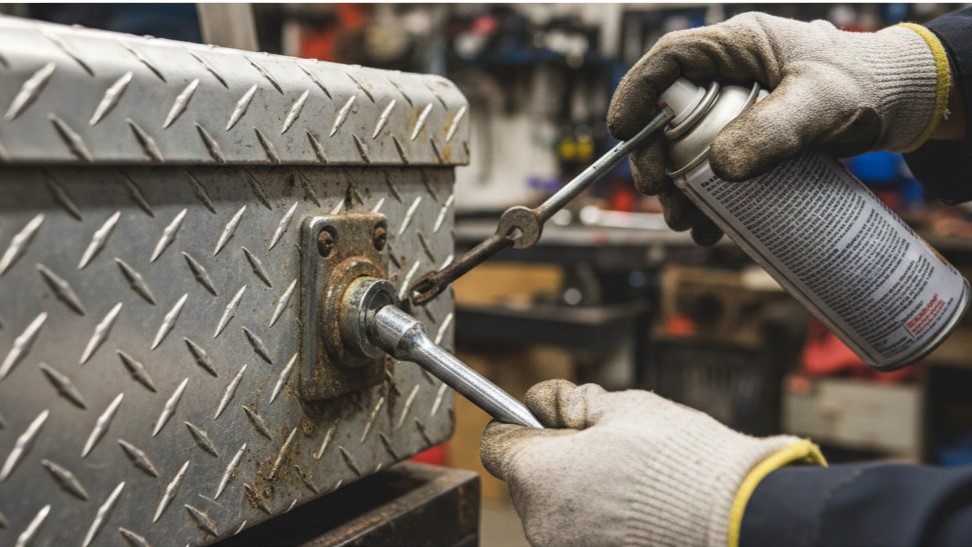

Picture this: You've just finished a long day on the job site, only to discover that your truck tool box lock has rusted shut—or worse, your valuable tools have been stolen because the lock gave way under pressure. If this scenario keeps you up at night, you're not alone. The lock on your truck tool box is the gatekeeper between your livelihood and potential disaster. Yet, with so many options flooding the market, choosing between stainless steel and aluminum truck tool box locks feels like navigating a technical minefield without a map.

This comprehensive guide cuts through the confusion. We'll dive deep into the material science behind these two industry giants, analyze real-world performance across security, weather resistance, durability, and cost considerations, and ultimately help you make an informed decision based on YOUR specific use case. Whether you're a fleet manager watching the bottom line, a coastal contractor battling salt air, or an individual truck owner seeking peace of mind, this guide has you covered.

Understanding the Contenders: Material Deep Dive

What Makes Stainless Steel Tick?

Stainless steel is an iron-based alloy containing a minimum of 10.5% chromium, which forms a passive oxide layer that acts as a protective shield against rust and corrosion. When it comes to truck tool box locks, you'll primarily encounter 304 stainless steel (the most common grade for consumer and commercial applications) and occasionally 316 stainless steel (the "marine grade" with added molybdenum for superior chloride resistance). The 304 grade, often called "18-8 stainless steel" because of its 18% chromium and 8% nickel composition, offers an exceptional balance of corrosion resistance, strength, and formability that makes it ideal for heavy-duty hardware applications.

The material characteristics of stainless steel translate directly into lock performance. With a tensile strength typically ranging from 70,000 to 100,000 PSI (depending on the exact alloy and temper), stainless steel resists deformation under stress, making it exceptionally difficult for would-be thieves to pry or force open. The hardness also means drill bits bite slowly and unpredictably, adding significant time and noise to any forced entry attempt. When you hold a stainless steel truck tool box lock, you're holding a piece of industrial-grade engineering designed to withstand years of punishment.

The Case for Aluminum in Hardware Applications

Aluminum is a lightweight wonder metal that has revolutionized the truck accessories industry over the past several decades. Unlike steel, aluminum doesn't rust in the traditional sense—instead, it forms a natural oxide layer that protects the underlying metal from corrosion. This characteristic makes aluminum tool boxes and locks particularly attractive for applications where weight savings and rust prevention are priorities. Most aluminum truck tool box locks are made from 5052 or 6061 alloy, both of which offer excellent corrosion resistance and adequate strength for medium-duty applications.

The weight advantage of aluminum cannot be overstated. A pure aluminum lock assembly might weigh 40-60% less than its stainless steel equivalent, which translates to measurable fuel savings over time, especially for fleets operating dozens or hundreds of trucks. For contractors who constantly remove and reinstall tool boxes or who worry about payload restrictions, the weight difference becomes a practical consideration rather than a mere statistic. Aluminum also offers a distinct aesthetic advantage, with its natural matte finish and the popular diamond-tread plate pattern providing a classic work truck look that many owners prefer over the clinical shine of polished stainless steel.

Aluminum Advantages

- Natural corrosion resistance without coatings

- 40-60% lighter than stainless steel

- Cost-effective for budget-conscious buyers

- Classic aesthetic with diamond plate options

- Excellent for medium-duty applications

Aluminum Limitations

- Lower tensile strength than stainless steel

- More susceptible to forced entry

- Can deform under sustained pressure

- Limited drill resistance compared to steel

- May not meet high-security requirements

Detailed Comparison: Steel vs. Aluminum Lock Performance

| Factor | Stainless Steel Lock | Aluminum Lock | Winner |

|---|---|---|---|

| Security & Strength | Exceptional tensile strength; resists prying and forced entry; drill-resistant | Adequate for light-to-medium duty; can deform under sustained force | Stainless Steel |

| Weather Resistance | Excellent; especially 316 grade; requires minimal maintenance | Natural oxide layer prevents rust; performs well in all conditions | Tie (Context Dependent) |

| Weight | Heavier; adds to overall truck payload | Lightweight; reduces strain on mounting hardware | Aluminum |

| Aesthetics | Polished modern look; professional appearance | Classic work truck style; diamond plate available | Personal Preference |

| Cost | Premium pricing; higher initial investment | Budget-friendly; lower cost of entry | Aluminum |

| Longevity | Decades of service with minimal maintenance | Excellent lifespan; no rust concerns | Tie |

Security and Strength: Where Steel Reigns Supreme

When it comes to security, the differences between stainless steel and aluminum become most pronounced under duress. A quality stainless steel paddle latch or T-handle lock offers tensile strength that makes forced entry extremely difficult and time-consuming. The material's resistance to deformation means that prying tools encounter a solid barrier that won't bend or twist under pressure. Furthermore, the hardness of stainless steel (typically 70-95 on the Rockwell scale for hardware-grade alloys) causes drill bits to wander, produce excessive noise, and require multiple bit changes—factors that dramatically increase the risk and effort required for theft.

Aluminum locks, while far from insecure, simply cannot match this level of resistance. The softer metal (typically 25-60 Rockwell hardness for common alloys) deforms more easily under prying pressure and allows drill bits to bite more aggressively. This doesn't mean aluminum locks are inadequate—for many users in low-theft areas or with medium-duty security needs, they provide entirely adequate protection. However, if your tool collection represents significant value or if you frequently park in high-risk areas, stainless steel's superior strength becomes a compelling argument for the modest price premium.

Weather and Corrosion Resistance: A Tale of Two Approaches

Both materials excel in corrosion resistance, but they achieve it through fundamentally different mechanisms. Stainless steel's chromium oxide layer provides passive protection that renews itself when damaged—if you scratch a stainless steel surface, fresh chromium reacts with oxygen to reform the protective layer. However, this protection can fail in harsh environments, particularly coastal areas with salt spray, where pitting corrosion can occur if the chloride concentration exceeds the material's resistance threshold. This is why marine applications often specify 316 stainless steel with its added molybdenum, which enhances resistance to chloride attack by 2-3 times compared to standard 304 grade.

Aluminum's corrosion resistance works differently but proves equally effective for most applications. The aluminum oxide layer that forms naturally on the surface is extremely hard and adherent, preventing further oxidation of the underlying metal. Unlike iron-based rust, which flakes away and exposes fresh metal to continued corrosion, aluminum oxide stays bonded to the surface and continues protecting the material below. For truck tool box locks used in normal conditions—rain, snow, humidity, occasional road salt—aluminum's corrosion resistance is entirely adequate and requires no additional coatings or treatments to maintain performance over time.

Which Lock Should You Buy? Real-World Scenarios

Scenario 1: The Coastal Contractor

Your Situation: You run a construction business along the Gulf Coast or Pacific coast, where salt air is a constant presence. Your tools represent a significant investment, and you need hardware that will survive years of maritime conditions without corroding.

Recommended Solution: Either a 316 stainless steel lock (marine-grade with enhanced chloride resistance) or a quality aluminum lock. While 316 stainless commands a premium price, it offers the ultimate in corrosion resistance for extreme environments. However, many aluminum locks perform equally well in coastal conditions at a lower cost, making them an intelligent budget-conscious choice. If you value the additional security margin that stainless provides and budget allows, 316 stainless steel is the premium choice. If you want excellent corrosion resistance without premium pricing, aluminum delivers reliable performance that will serve you well for years.

Scenario 2: The Inner-City Tradesperson

Your Situation: You work in an theft risk. urban environment with high Your truck often parks on job sites where tools could be targeted. Security is your primary concern, and you're willing to invest in hardware that makes forced entry as difficult as possible.

Recommended Solution: 304 stainless steel heavy-duty paddle latch or T-handle lock with reinforced construction. The superior strength and drill resistance of stainless steel provide the security margin you need in high-theft environments. Look for features like reinforced backplates, multiple locking points, and pick-resistant cylinder mechanisms. While aluminum locks provide basic security, they simply cannot match the resistance to forced entry that stainless steel offers. For peace of mind in urban environments, stainless steel's additional security is worth the investment.

Scenario 3: The Budget Fleet Manager

Recommended Solution: Quality aluminum locks offer the best balance of cost, weight, and performance for fleet applications. The 40-60% weight savings compared to stainless steel translates to measurable fuel savings across hundreds of thousands of miles. Aluminum's natural corrosion resistance means less maintenance and fewer replacement cycles. For fleet applications where maximum security is less critical than cost-effectiveness and reliability, aluminum delivers excellent value. Look for reputable brands with solid construction quality—the cheapest aluminum locks may save money upfront but cost more in replacement and maintenance over time.

Scenario 4: The Individual Truck Owner

Your Situation: You own a personal truck and want to secure your tools for occasional DIY projects and weekend work. You want reliable performance without premium pricing, and you appreciate hardware that will maintain its appearance with minimal maintenance.

Recommended Solution: Either material works well for personal use, and your choice should reflect your specific priorities. If you value the polished, professional look of stainless steel and want maximum security for occasional high-value tool storage, stainless steel is an excellent choice. If you prefer the classic work truck aesthetic, want to minimize weight, or prefer aluminum's natural rust resistance without special coatings, quality aluminum locks deliver reliable performance at a lower price point. For most individual owners in moderate climates with moderate theft risk, both options provide adequate security—the right choice is whichever aligns with your preferences and budget.

Maintenance and Care: Extending Lock Lifespan

Regardless of which material you choose, proper maintenance significantly extends the life and performance of your truck tool box lock. Both stainless steel and aluminum locks benefit from regular cleaning to remove road grime, salt deposits, and debris that can compromise seals and accelerate wear. A simple quarterly cleaning with mild soap and water, followed by thorough drying, removes corrosive contaminants and keeps the lock mechanism operating smoothly.

Lubrication Best Practices

For the locking mechanism itself, use graphite-based lubricants rather than oil-based products. Graphite is dry, doesn't attract dirt and debris, and provides excellent lubrication for keyway and latch mechanisms. AvoidWD-40 and similar products for long-term use—they can actually attract contaminants that accelerate wear over time. Apply lubricant sparingly to the keyway and moving parts, then work the lock several times to distribute the lubricant evenly.

Seasonal Maintenance Checklist

- Inspect the lock cylinder for signs of wear or damage

- Clean debris from around the latch mechanism

- Check mounting hardware for tightness

- Test the lock operation with the key

- Lubricate moving parts with graphite-based product

- Inspect weather seals for damage or deterioration

For stainless steel locks in coastal or winter road-salt environments, occasional polishing with a stainless steel cleaner helps maintain the protective chromium oxide layer and keeps your lock looking new. Aluminum locks generally require less maintenance but benefit from occasional cleaning to remove oxidation that can accumulate in harsh conditions. With proper care, both stainless steel and aluminum truck tool box locks will provide years of reliable service, protecting your valuable tools through countless job site adventures.

Making Your Final Decision

After examining the strengths, limitations, and ideal applications for both stainless steel and aluminum truck tool box locks, one truth becomes clear: there is no universally "better" material—only the right material for your specific needs. Stainless steel offers unmatched strength and security, making it the preferred choice for high-value tool storage, high-theft-risk environments, and users who prioritize peace of mind above all else. Its durability and corrosion resistance (especially in marine-grade 316 alloy) ensure decades of reliable service, though this premium performance comes with a higher price tag and additional weight.

Aluminum, meanwhile, provides an compelling combination of natural corrosion resistance, significant weight savings, and cost-effectiveness that makes it ideal for fleet applications, budget-conscious buyers, and users with moderate security needs. Its lighter weight contributes to fuel efficiency and reduces strain on mounting hardware, while its classic aesthetic appeals to those who value the traditional work truck look. For many users, aluminum delivers more than adequate security and durability at a price point that makes sense for their budget.

Consider your specific situation honestly: What is the value of the tools you're protecting? What is the theft risk in your typical parking locations? How important is weight and fuel efficiency to your operation? What is your budget for hardware? By answering these questions clearly, you'll find that the choice between stainless steel and aluminum becomes surprisingly straightforward. Both materials represent mature, proven technologies that serve their intended purposes well—the key is matching the right material to the right application.

Ready to Upgrade Your Truck's Security?

Whether you're looking for heavy-duty stainless steel locks that provide maximum security or lightweight aluminum solutions that combine practicality with reliable performance, Eastsea Machinery has you covered. As a trusted supplier of industrial-grade truck tool box hardware, we understand that quality locks are an investment in protecting your livelihood.

Explore our comprehensive selection of stainless steel truck tool box locks and aluminum truck tool box locks to find the perfect solution for your needs. Our expert team is ready to help you select the right hardware for your specific application.

Contact Our Team for Expert Guidance