Stainless Steel vs. Zinc Alloy Truck Tool Box Locks: Which Is Better?

Your Ultimate Guide to Choosing the Right Material for Durability, Security & Performance

At East Sea Machinery, a trusted truck tool box lock manufacturer since 2002, we understand that the security and longevity of your vehicle’s storage compartments depend heavily on one critical component: the lock material.

Among the most common materials used in truck tool box locks—stainless steel and zinc alloy—each offers distinct advantages and trade-offs.

In this comprehensive guide, we’ll compare stainless steel vs. zinc alloy truck tool box locks across key factors like corrosion resistance, strength, durability, cost, and environmental performance, helping you make an informed, expert-backed decision. Backed by over two decades of manufacturing experience and certified quality standards, East Sea Machinery delivers professional insights you can trust.

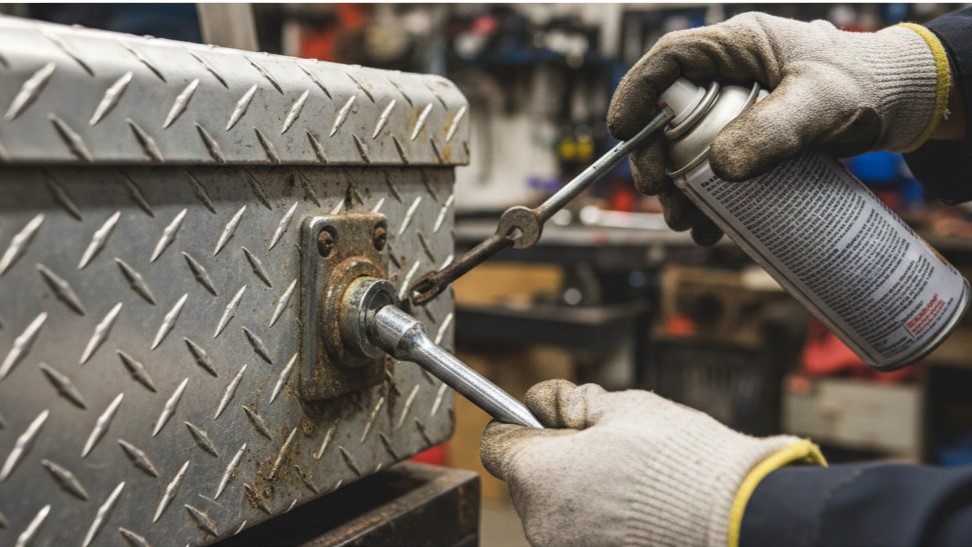

Why Lock Material Matters for Truck Tool Boxes

Truck tool boxes are exposed to extreme conditions: road salt, moisture, UV radiation, vibration, and temperature fluctuations. The lock—the first line of defense—must withstand these challenges while ensuring reliable access and theft resistance.

Choosing between stainless steel and zinc alloy isn’t just about cost—it’s about matching the material to your operational environment, usage frequency, and long-term value.

Let’s dive into the detailed comparison.

1. Material Composition & Manufacturing Expertise

Stainless Steel

Stainless steel is an iron-based alloy containing at least 10.5% chromium, which forms a passive oxide layer that resists rust and corrosion. Common grades used in locks include 304 and 316, known for excellent weather and chemical resistance.

At East Sea Machinery, our Model 19204-B features 304 stainless steel construction with a polished finish and waterproof cap, engineered for marine-grade durability.

Zinc Alloy (Zamak)

Zinc alloy (often Zamak 3 or Zamak 5) is a cast metal composed of zinc with small amounts of aluminum, magnesium, and copper. It’s lightweight, cost-effective, and ideal for complex shapes due to its excellent castability.

While widely used in automotive and industrial hardware, zinc alloy requires protective plating (e.g., chrome, nickel, or powder coating) to resist corrosion.

Head-to-Head Comparison: Stainless Steel vs. Zinc Alloy

| Feature | Stainless Steel Locks | Zinc Alloy Locks |

|---|---|---|

| Corrosion Resistance | Excellent – naturally rust-resistant | Fair – requires plating; prone to white rust under moisture |

| Strength & Impact Resistance | High tensile strength, resists deformation | Good for light-duty use; may crack under heavy impact |

| Durability (Long-Term Use) | Lasts 10+ years in harsh environments | 3–7 years, depending on coating integrity |

| Weight | Heavier (adds structural stability) | Lighter (easier to install) |

| Aesthetic Finish | Polished, satin, or brushed – retains luster | Can be chrome-plated or painted; may peel or fade |

| Temperature Resistance | Performs well from -50°C to 600°C | Degrades above 100°C; not ideal for extreme heat |

| Cost | Higher initial investment | More budget-friendly |

| Environmental Suitability | Ideal for coastal, winter, and industrial zones | Best for dry, indoor, or mild climates |

2. Corrosion Resistance: The #1 Factor for Truck Applications

Stainless steel wins decisively in environments with:

- Road salt (common in winter regions)

- Coastal exposure (salt spray)

- High humidity or frequent rain

- Chemical exposure (e.g., cleaning agents, fuels)

Zinc alloy locks, even with plating, are vulnerable to galvanic corrosion when in contact with dissimilar metals (like aluminum tool boxes) in wet conditions. Over time, this leads to “white rust” (zinc oxide) and eventual structural failure.

Pro Tip from East Sea Engineers:

In marine or northern climates, stainless steel locks reduce maintenance and replacement costs by up to 60% over 5 years compared to zinc alloy.

Our 304 Stainless Steel Polishing Folding T-Handle Lock (Model 19204-B) is specifically designed for these harsh environments, featuring a waterproof cap and seamless sealing to prevent moisture ingress.

3. Strength & Security: Protecting Your Tools & Equipment

Stainless steel has higher tensile and yield strength, making it more resistant to:

- Prying

- Drilling

- Impact attacks

This makes stainless steel locks ideal for high-theft-risk areas or commercial fleets where tool security is critical.

Zinc alloy, while strong for its weight, is more brittle and can fracture under sustained force. It’s better suited for light-duty or occasional-use applications.

East Sea Recommendation:

For contractors, utility fleets, and emergency vehicles, upgrade to stainless steel for enhanced security and peace of mind.

4. Cost Analysis: Upfront vs. Long-Term Value

| Cost Factor | Stainless Steel | Zinc Alloy |

|---|---|---|

| Initial Purchase Price | Higher (~30–50% more) | Lower |

| Maintenance | Minimal (no recoating needed) | May require cleaning, lubrication, or re-plating |

| Replacement Frequency | Rare (10+ year lifespan) | Moderate (3–7 years) |

| Total Cost of Ownership (TCO) | Lower over time | Higher due to replacements |

While zinc alloy locks offer short-term savings, stainless steel delivers superior long-term value, especially in demanding applications.

5. Environmental & Sustainability Considerations

Stainless Steel:

- 100% recyclable

- No surface coatings required

- Low environmental impact over lifecycle

Zinc Alloy:

- Recyclable, but energy-intensive to reprocess

- Plating processes may involve hazardous chemicals

- Shorter lifespan = more waste

For eco-conscious fleets and manufacturers, stainless steel aligns better with sustainability goals.

6. Application Scenarios: Which Material Fits Your Needs?

Choose Stainless Steel If You Need:

- Maximum corrosion resistance (coastal, winter, industrial)

- Long-term durability with minimal maintenance

- High security for valuable tools

- Compliance with marine or military standards

- A premium, professional appearance

Recommended East Sea Products:

- Model 19204-B: 304 Stainless Steel Polishing Folding T-Handle Lock with Waterproof Cap

- Model 19102: Whale Tail T-Folding Handle Lock (stainless variants available)

Choose Zinc Alloy If You Need:

- Budget-friendly solution for dry, indoor, or light-duty use

- Lightweight design for non-critical applications

- Complex shapes or decorative finishes

Recommended East Sea Products:

- Model 19105: I-Handle Round Lock (zinc alloy with chrome plating)

- Model 19302A: Pull-Open Panel Lock (durable zinc construction)

Why Trust East Sea Machinery?

As a professional manufacturer since 2002, East Sea Machinery combines innovative engineering, rigorous quality control, and customer-centered customization to deliver locks that perform in real-world conditions.

Our products are backed by:

- ISO 9001 Certification for quality management

- CE and RoHS Compliance for international safety and environmental standards

- In-house R&D team with 20+ years of industry expertise

- Custom OEM/ODM services for fleet-specific requirements

We don’t just sell locks—we provide one-stop customization solutions tailored to your vehicle, climate, and security needs.

Frequently Asked Questions (FAQ)

Q: Can zinc alloy locks be used outdoors?

A: Yes, but only in dry or mildly humid environments. In wet or salty conditions, they degrade faster than stainless steel.

Q: Is stainless steel rust-proof?

A: While highly corrosion-resistant, stainless steel can rust if scratched and exposed to chlorides over time. Proper maintenance ensures longevity.

Q: Can I upgrade my existing tool box to stainless steel locks?

A: Absolutely. Our locks are designed for standard mounting patterns and easy retrofitting. Contact us for compatibility support.

Q: Do you offer custom finishes or keyed-alike options?

A: Yes. East Sea Machinery provides custom polishing, engraving, keying, and packaging—ideal for fleet operators.

Final Verdict: Which Is Better?

| Use Case | Recommended Material |

|---|---|

| Harsh environments (salt, moisture, cold) | Stainless Steel |

| High-security needs | Stainless Steel |

| Long-term cost efficiency | Stainless Steel |

| Budget-limited, light-duty use | Zinc Alloy |

| Aesthetic flexibility | Zinc Alloy (plated options) |

Bottom Line:

For truck tool box locks, stainless steel is the superior choice in terms of durability, security, and total value—especially in demanding environments. While zinc alloy offers affordability, it falls short in longevity and corrosion resistance.

At East Sea Machinery, we recommend investing in stainless steel for any application where reliability and protection matter.

Ready to Upgrade Your Truck Locks?

Explore our full range of professional-grade truck tool box locks, including the best-selling 304 Stainless Steel Folding T-Handle Lock (Model 19204-B), engineered for performance you can count on.

Contact East Sea Machinery today for free samples, custom quotes, or technical consultation.

Visit https://www.eastseamachinery.com/ to discover your one-stop customization solution.

East Sea Machinery – Innovative Manufacturing Since 2002

Your Trusted Partner in Secure, Durable, and High-Performance Lock Solutions.

-

Jul 16, 2025What Are the Different Types of Toolbox Locks?(Comprehensive Guide)

Jul 16, 2025What Are the Different Types of Toolbox Locks?(Comprehensive Guide) -

Sep 18, 2025Top 10 Most Popular Pickup Truck Models in the Americas in 2025

Sep 18, 2025Top 10 Most Popular Pickup Truck Models in the Americas in 2025 -

Sep 11, 2025Top 10 Truck Tool Box Lock Manufacturers in the World

Sep 11, 2025Top 10 Truck Tool Box Lock Manufacturers in the World -

Sep 30, 2025Top 10 Most Common Special Purpose Vehicles in North America

Sep 30, 2025Top 10 Most Common Special Purpose Vehicles in North America