How Contractors Can Reduce Tool Theft with Upgraded Truck Box Locks

_1763615579_WNo_1600d900.webp)

The Rising Cost of Equipment Theft in the Construction Industry

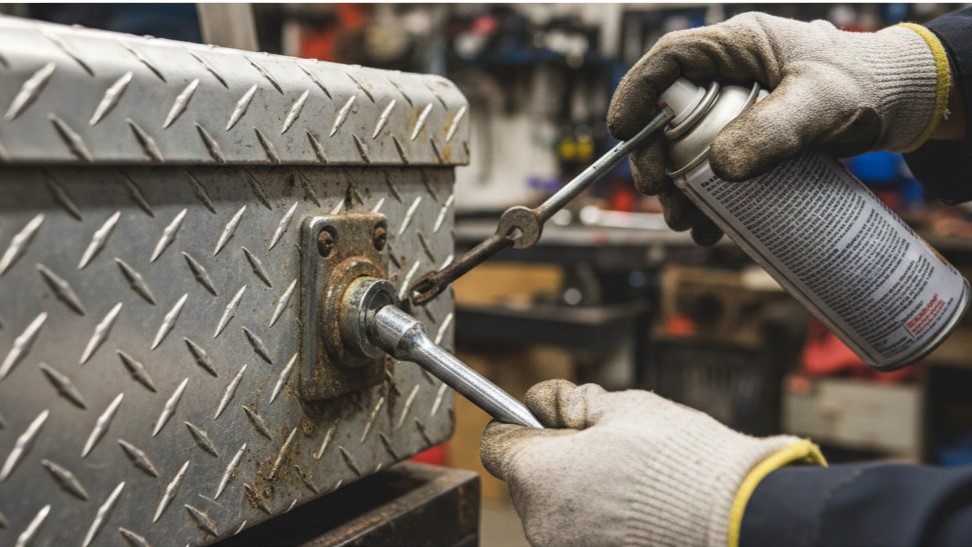

For general contractors and fleet managers, tool theft is more than a nuisance—it is a significant operational risk that directly impacts the bottom line. While the immediate cost of replacing power tools, generators, and specialized equipment is substantial, the indirect costs often prove far more damaging to a business.

When a service truck is broken into, the immediate result is operational downtime. Crews are unable to perform scheduled tasks, leading to project delays and potential contract penalties. Furthermore, frequent claims can lead to increased insurance premiums and higher deductibles. Since service bodies and toolboxes are often targeted while parked at job sites or overnight in unsecured lots, the security of the truck box itself becomes the first line of defense. Relying on inadequate locking mechanisms not only jeopardizes valuable assets but also threatens the continuity of daily operations.

Identifying Vulnerabilities in Standard and OEM Truck Box Latches

Many work trucks and service bodies come equipped with standard OEM (Original Equipment Manufacturer) latches designed primarily for general closure rather than high-security protection. While these components function adequately for basic retention, they often present specific vulnerabilities that thieves exploit.

The primary weakness often lies in the material composition. Standard latches are frequently manufactured from die-cast zinc or mild steel. While cost-effective, these materials are more brittle than heavy-duty alternatives and can shatter under the force of a pry bar or hammer. Additionally, standard locking cylinders typically utilize basic wafer tumblers, which offer low resistance to drilling or picking. In some fleet scenarios, the use of universal key codes—meant for convenience—can inadvertently allow unauthorized access if master keys are easily obtained.

Furthermore, the design of standard flush-mount handles often lacks internal reinforcement. Over time, exposure to road salts and moisture can cause corrosion in the internal spring mechanisms and pivot points, weakening the latch's structural integrity and making it easier to force open without specialized tools.

Key Features of High-Security Truck Box Locks

To effectively mitigate theft, upgrading to high-security locking hardware requires understanding specific engineering features that deter forced entry. Unlike standard closures, high-security locks are designed with resistance mechanisms that counter common attack methods such as drilling, prying, and cutting.

When evaluating upgraded hardware, contractors should prioritize the following technical attributes:

-

Flush-Mount Geometry: High-security paddle handles and recessed latches are designed to sit flush against the truck body. This minimizes the surface area available for a thief to grip with pliers or wedge a pry bar under, significantly reducing leverage.

-

Drill-Resistant Cylinders: Superior locks utilize solid brass cylinders or automotive-grade disc tumblers rather than simple wafer mechanisms. These cylinders are often equipped with hardened steel faceplates or drill-guard pins that prevent the internal mechanism from being destroyed by standard drill bits.

-

Concealed Mounting Studs: Secure hardware relies on blind mounting studs that are welded to the back of the latch pan. This ensures that there are no visible screw heads or bolts on the exterior of the box that can be removed or sheared off.

-

Weather Sealing and Gaskets: While primarily for environmental protection, robust rubber gaskets prevent water and road salt ingress. Preventing corrosion is a security measure; a rusted lock mechanism is brittle and far easier to shatter than a well-maintained, lubricated component.

Material Selection: Why Stainless Steel Hardware Offers Superior Security

The material composition of a truck box lock is the most critical factor determining its resistance to physical attacks. While zinc die-cast and mild steel latches are common in standard applications, they lack the tensile strength and impact resistance required for high-security applications. For contractors seeking maximum protection, industrial-grade stainless steel is the superior choice.

AISI 304 Stainless Steel The industry standard for upgraded truck body hardware is AISI 304 stainless steel. This austenitic grade offers a high yield strength, making it significantly harder to bend or deform compared to carbon steel or zinc alloys. When a lock body resists deformation, it prevents the internal mechanism from becoming misaligned during a prying attempt, keeping the latch engaged.

Corrosion as a Security Risk Corrosion is not merely an aesthetic issue; it is a structural vulnerability. In environments where service trucks are exposed to road salts, de-icing chemicals, or marine air, mild steel latches can rust from the inside out. This corrosion compromises the spring mechanisms and weakens the latch pan, making it susceptible to shattering under impact. Stainless steel naturally forms a passive layer of chromium oxide that prevents this degradation.

Grade 316 for Extreme Environments For fleets operating in particularly harsh conditions—such as coastal construction sites or northern regions with heavy salt usage—upgrading to AISI 316 stainless steel provides an added layer of security. The addition of molybdenum in Grade 316 enhances resistance to pitting and crevice corrosion, ensuring that the locking hardware maintains its structural integrity and mechanical smooth operation over the vehicle's entire service life.

Upgrading Mechanisms: Heavy-Duty Paddle Handles vs. T-Handle Locks

When upgrading truck box security, the mechanism of operation—specifically the handle type—dictates both the convenience for the operator and the level of protection against theft. The two most prevalent designs in the industrial market are heavy-duty paddle handles and folding T-handle locks. Understanding the mechanical differences between them is essential for selecting the right hardware for specific fleet requirements.

Heavy-Duty Paddle Handles (Slam Latches) Paddle handles, particularly those made from stainless steel, are the modern standard for service bodies. Their primary security advantage lies in their flush-mount profile. Because the handle remains recessed within the latch pan until actuated, there is no protruding lever for a thief to grip with a pipe wrench or pliers to force the lock rotation.

Mechanically, paddle handles are often paired with rotary latching systems. This design offers "slam-action" capability, meaning the door automatically latches when closed without requiring the operator to manually turn a handle. This feature reduces the likelihood of doors being left unlatched due to operator error, ensuring the security mechanism is engaged every time the door is closed.

Folding T-Handle Locks Folding T-handles fit into a recessed dish and fold down when not in use. While older, fixed T-handles were vulnerable to being twisted off with high-torque tools, modern folding designs mitigate this risk by hiding the handle grip.

The distinct advantage of the T-handle mechanism is mechanical leverage. The T-shape allows the operator to apply significant force to compress the door seal against the truck body frame. This is particularly beneficial for maintaining a watertight seal (IP rating) on boxes containing sensitive electronics or moisture-prone tools. However, for maximum security, T-handles must be utilized in conjunction with a multi-point rod system rather than a single-point cam, as a single cam can be bent backward with sufficient force.

The Role of Multi-Point Locking Systems in Preventing Pry Attacks

Even the most robust stainless steel latch can be bypassed if the locking points do not effectively secure the entire door perimeter. A common vulnerability in standard toolboxes is the reliance on a single-point locking system. In a single-point setup, the latch engages the frame only at the center of the door. This creates a "cantilever effect" at the corners, allowing thieves to wedge a pry bar at the top or bottom of the door and peel it back enough to extract valuable tools without ever touching the lock itself.

To counter this, contractors should retrofit service bodies with two-point or three-point locking systems.

How Multi-Point Systems Work In a multi-point configuration, the center handle (whether paddle or T-handle) operates a rotary mechanism that connects to steel control rods. When the handle is turned, these rods extend simultaneously to engage with striker plates or rollers located at the top and bottom of the door frame.

Technical Advantages:

-

Force Distribution: By securing the door at multiple locations, the force of a pry attack is distributed across the entire frame rather than concentrated on a single latch bolt. This makes peeling the door corners virtually impossible with manual tools.

-

Anti-Rack Stability: Multi-point systems add structural rigidity to the door. This is crucial for larger cabinet doors on service bodies, which can flex or warp over time due to vehicle vibration.

-

Rod Material: For maximum security, the connecting rods should be manufactured from heavy-gauge steel or stainless steel to prevent bending under tension.

Implementing a multi-point system transforms the truck box from a simple storage container into a secure vault, forcing thieves to bypass multiple failure points rather than just one.

Best Practices for Retrofitting and Maintaining Security Hardware

Upgrading a service truck fleet involves more than simply purchasing high-security latches; proper installation and ongoing maintenance are required to ensure the hardware performs as engineered. When retrofitting existing truck boxes with new stainless steel components, following technical best practices ensures long-term reliability.

Retrofitting Considerations Before purchasing replacement hardware, precise measurement of the existing cutout dimensions is mandatory. While many industry-standard latches share common footprints, slight variations in mounting stud spacing or pan depth can prevent a flush fit. When installing new latches on older doors where the metal may be fatigued, the use of internal reinforcement plates (backer plates) is recommended. These plates sandwich the door sheet metal, distributing the load of the latch and preventing the metal from tearing around the mounting studs during a forced entry attempt.

Vibration Management Service trucks operate in high-vibration environments. Standard nuts can loosen over time, causing the latch to rattle or even detach. For a secure installation, contractors should use nylon-insert lock nuts (Nyloc) or apply industrial-grade thread-locking compounds to the mounting studs. This ensures the hardware remains tight despite constant road vibration and door slamming.

Maintenance for Longevity To maintain the security integrity of the lock cylinder, regular maintenance is essential. Avoid using heavy grease or standard oils inside the keyway, as these substances attract dust and grit, which can jam the tumblers. Instead, use a dry graphite lubricant or a dedicated PTFE-based lock spray. Additionally, during the winter months, frequently washing the latch mechanism with fresh water to remove road salt accumulation will prevent crevice corrosion and ensure the handle springs remain responsive.

-

Jul 16, 2025What Are the Different Types of Toolbox Locks?(Comprehensive Guide)

Jul 16, 2025What Are the Different Types of Toolbox Locks?(Comprehensive Guide) -

Sep 18, 2025Top 10 Most Popular Pickup Truck Models in the Americas in 2025

Sep 18, 2025Top 10 Most Popular Pickup Truck Models in the Americas in 2025 -

Sep 11, 2025Top 10 Truck Tool Box Lock Manufacturers in the World

Sep 11, 2025Top 10 Truck Tool Box Lock Manufacturers in the World -

Sep 30, 2025Top 10 Most Common Special Purpose Vehicles in North America

Sep 30, 2025Top 10 Most Common Special Purpose Vehicles in North America